©2020, Full-Size Chevrolet Research Group

Edited by Warren Leunig

Version: Monday, 28-December-2020 09:57:20 EDT

The build sheet, more commonly referred to as a broadcast sheet, is that mysterious piece of paper that everyone wants to find and only a few do. It gives a breakdown of most of the components that were used to assemble the car. Most of these components are listed as a code, which appeared somewhere on the part. It may have been an ink stamp or a paper tag but the assembly line worker had to grab the correct one! This article will give you a breakdown of what the assembly plants used and where to find them, if they were left in the car at all!

- Fisher Body Assembly Plants

- BOP Assembly Plants

- Canadian Assembly Plants

- Seat tags

Fisher Body Assembly Plants

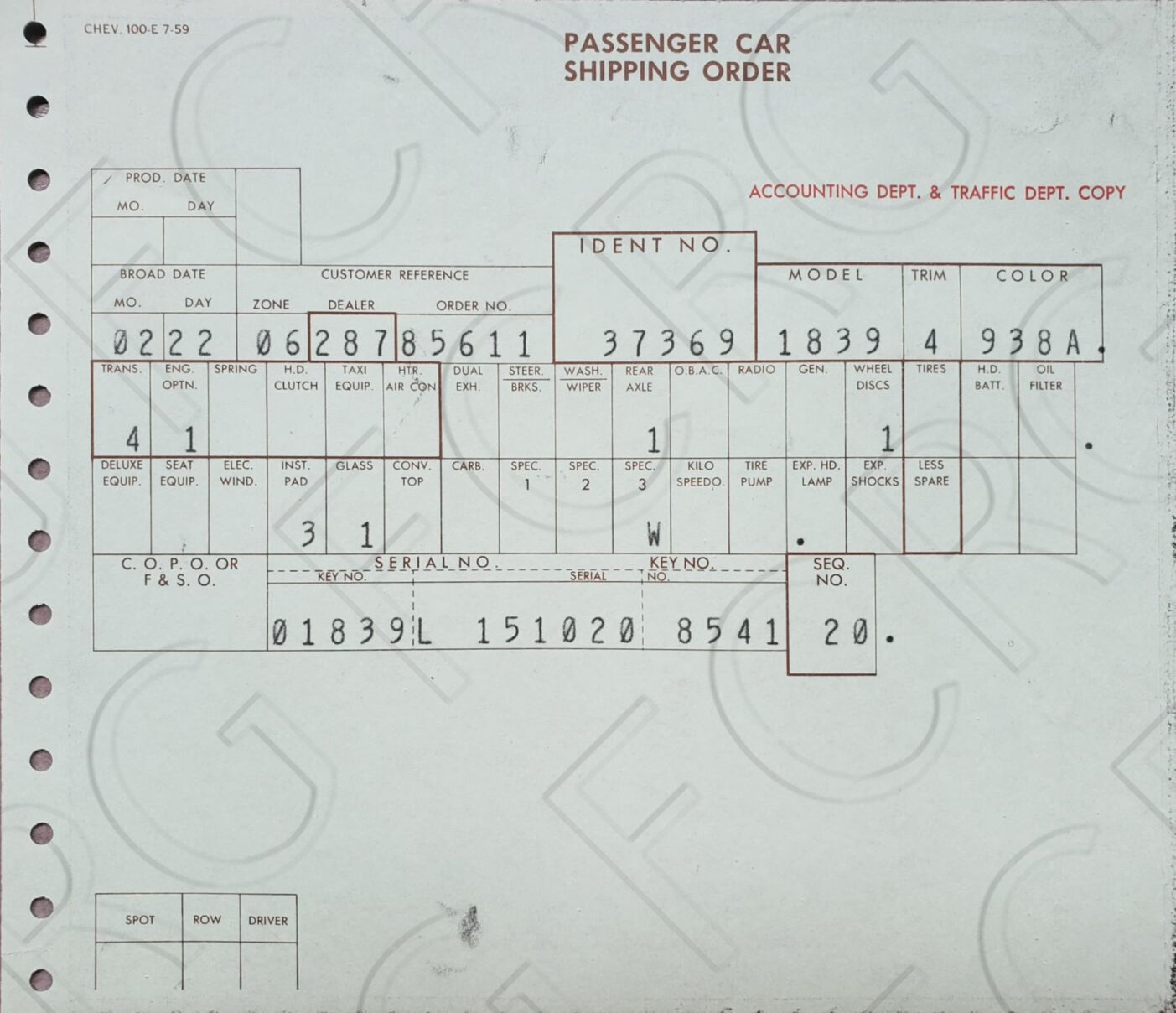

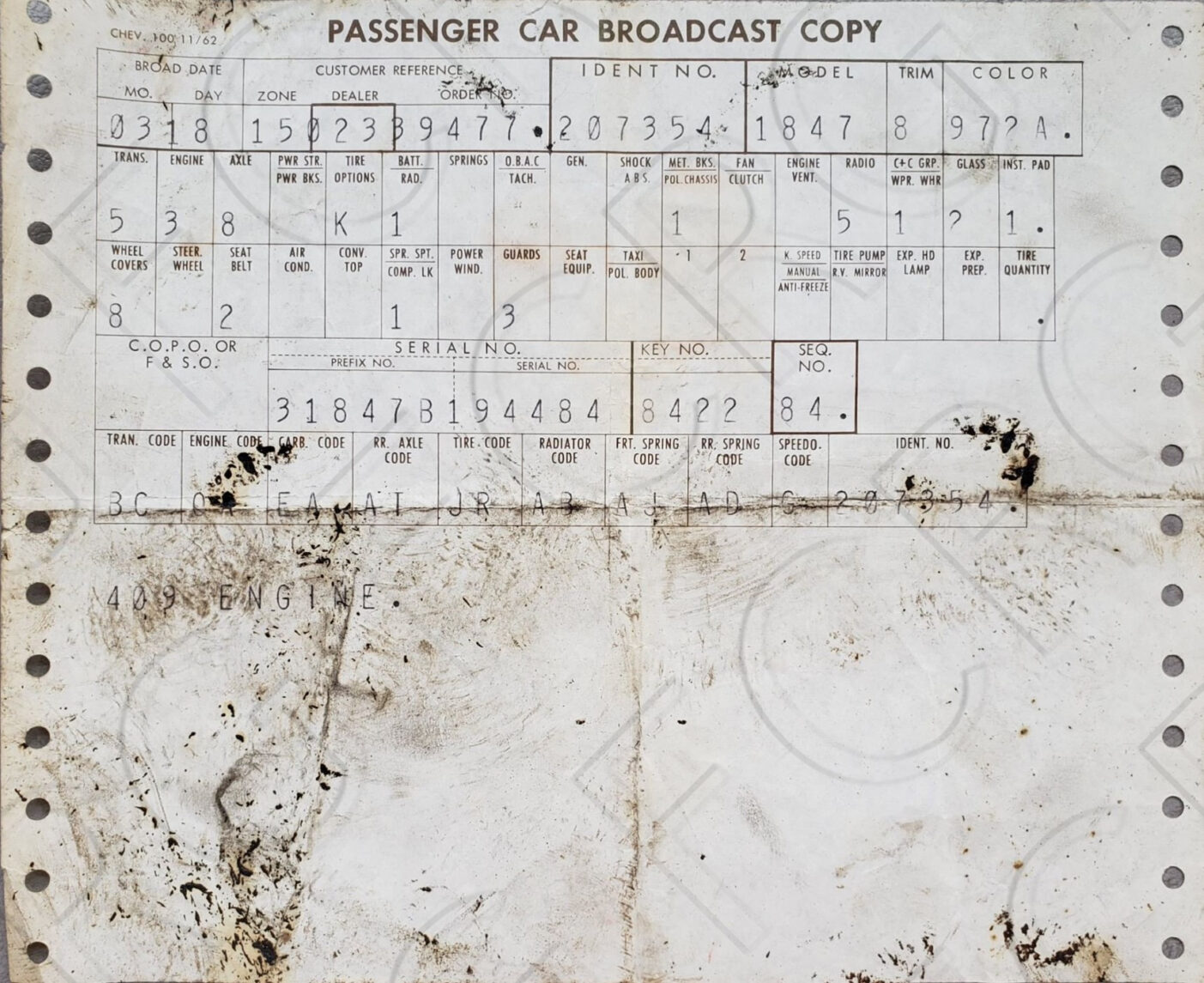

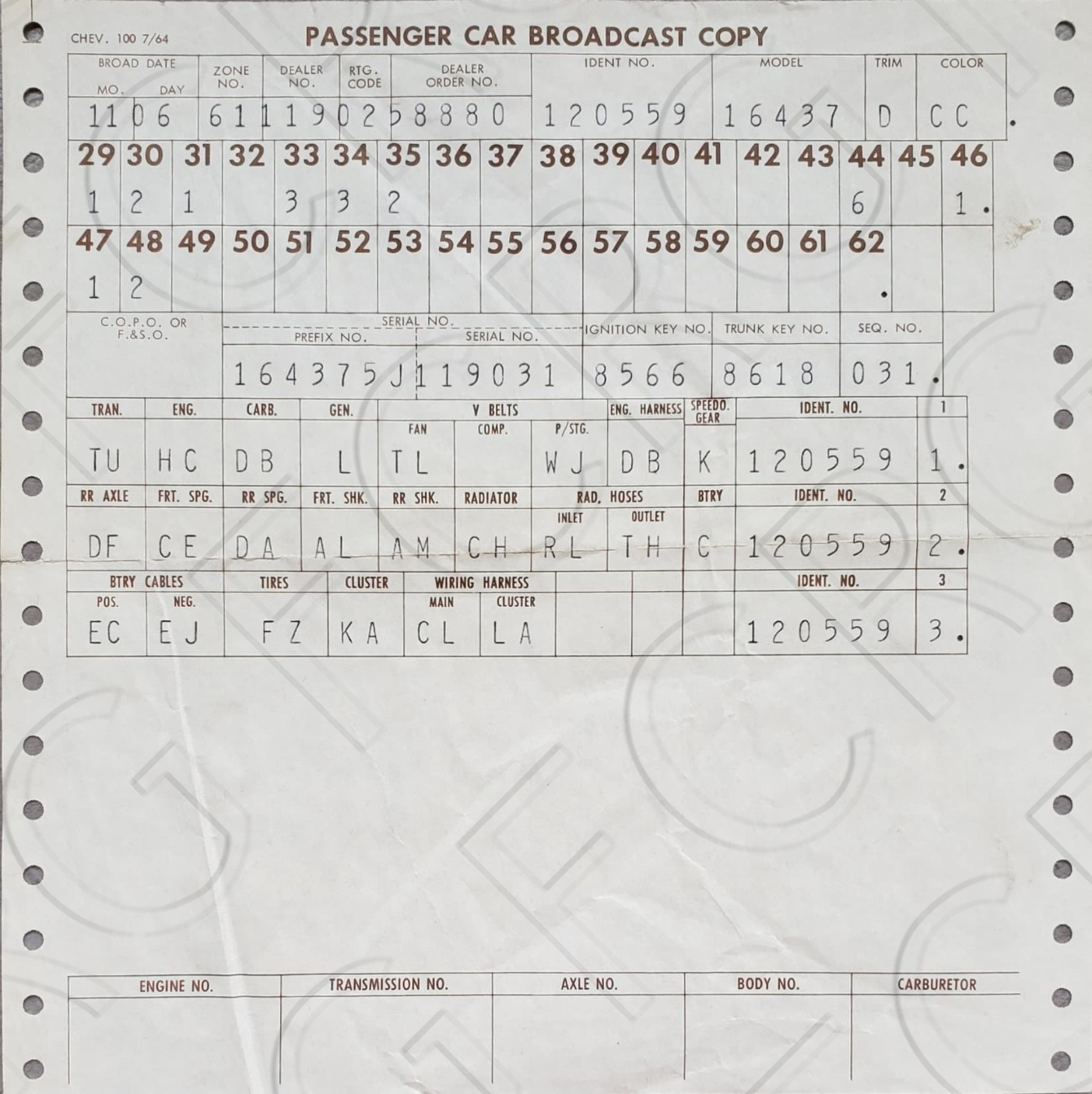

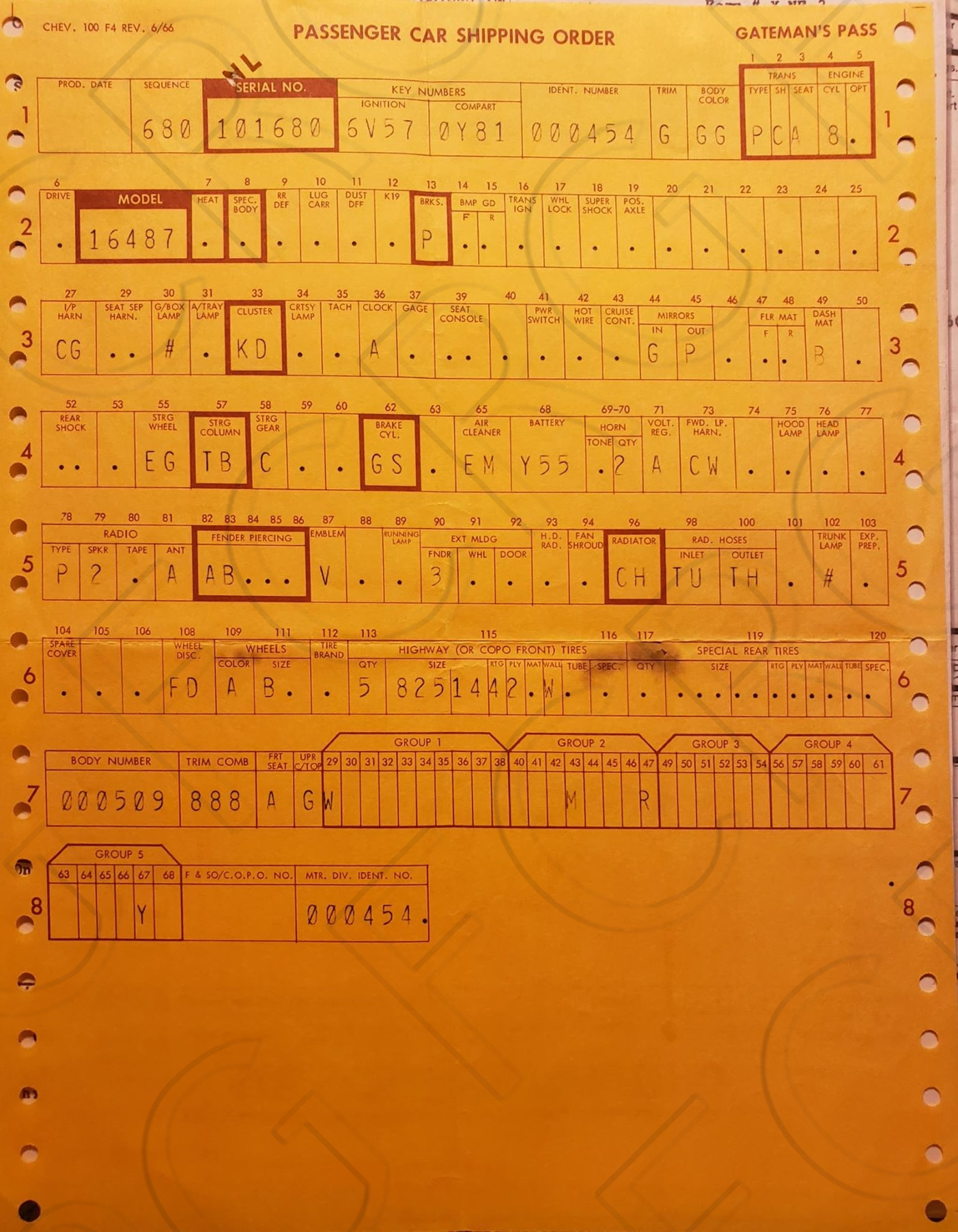

The Fisher Body assembly plants used a broadcast sheet going back to at least 1960. The forms they used typically had the word “broadcast” in the heading, such as “Passenger Car Broadcast Copy.” That was the main title of the form through the 1965 model year. It actually listed the options the car had in the format that appears on the original order form. Each option box could have a number under it, which corresponded to the option selected. For example, under the box for power steering and brakes in 1965, it could have 3 different numbers. A 1 meant power steering, a 2 meant power brakes and a 3 meant it had both options. Where the early version of the form listed only the options and dealer who ordered the car, by 65, it listed some of the parts used to build it. And there were multiple copies of the form for different sections of the assembly plant. The “Soft Trim Broadcast Copy” looked identical except some of the boxes were blacked out, leaving only interior related information. The sheet was printed with carbon paper between the pages so each copy got the same information. The following 3 photos show broadcast sheets from 60, 63 and 65.

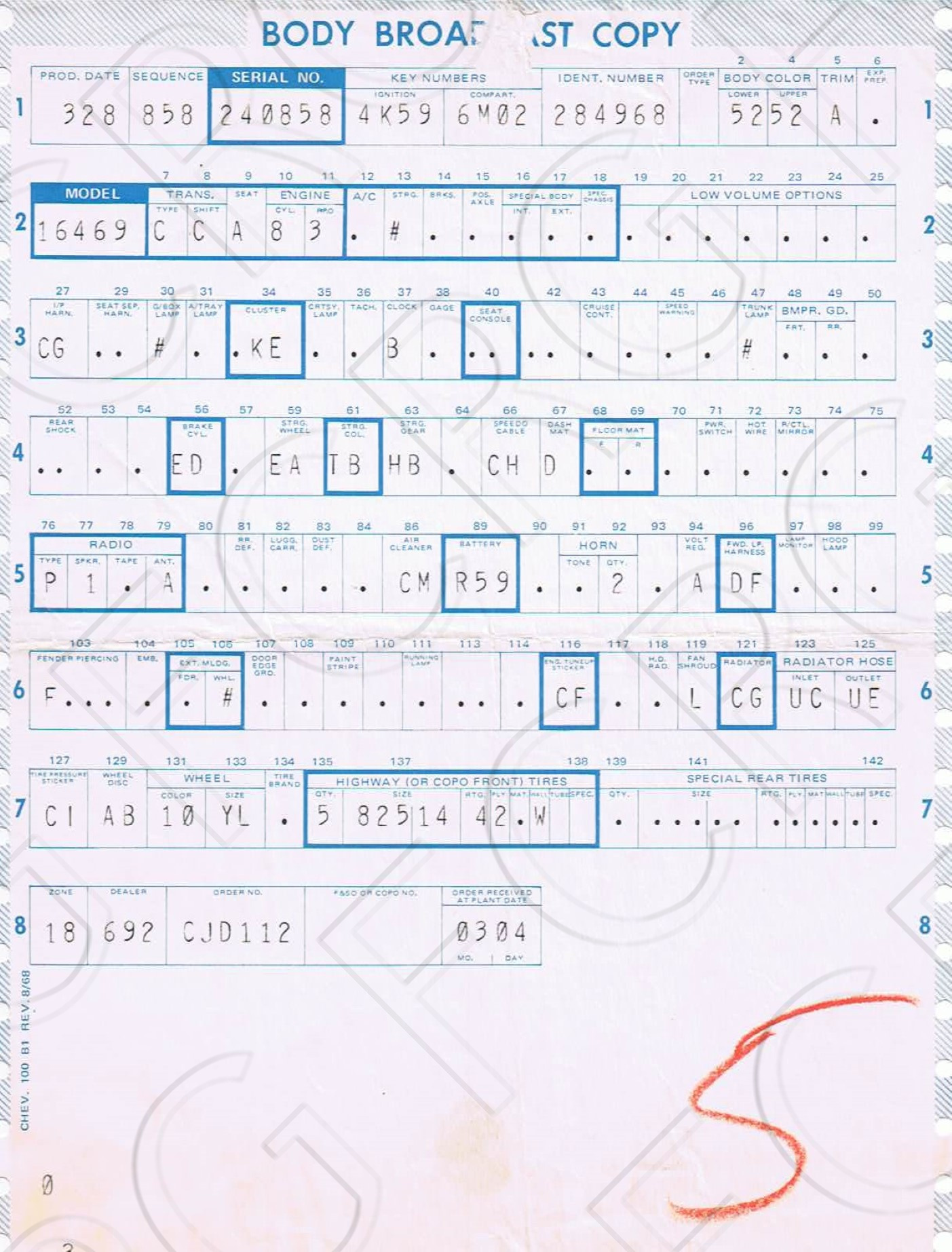

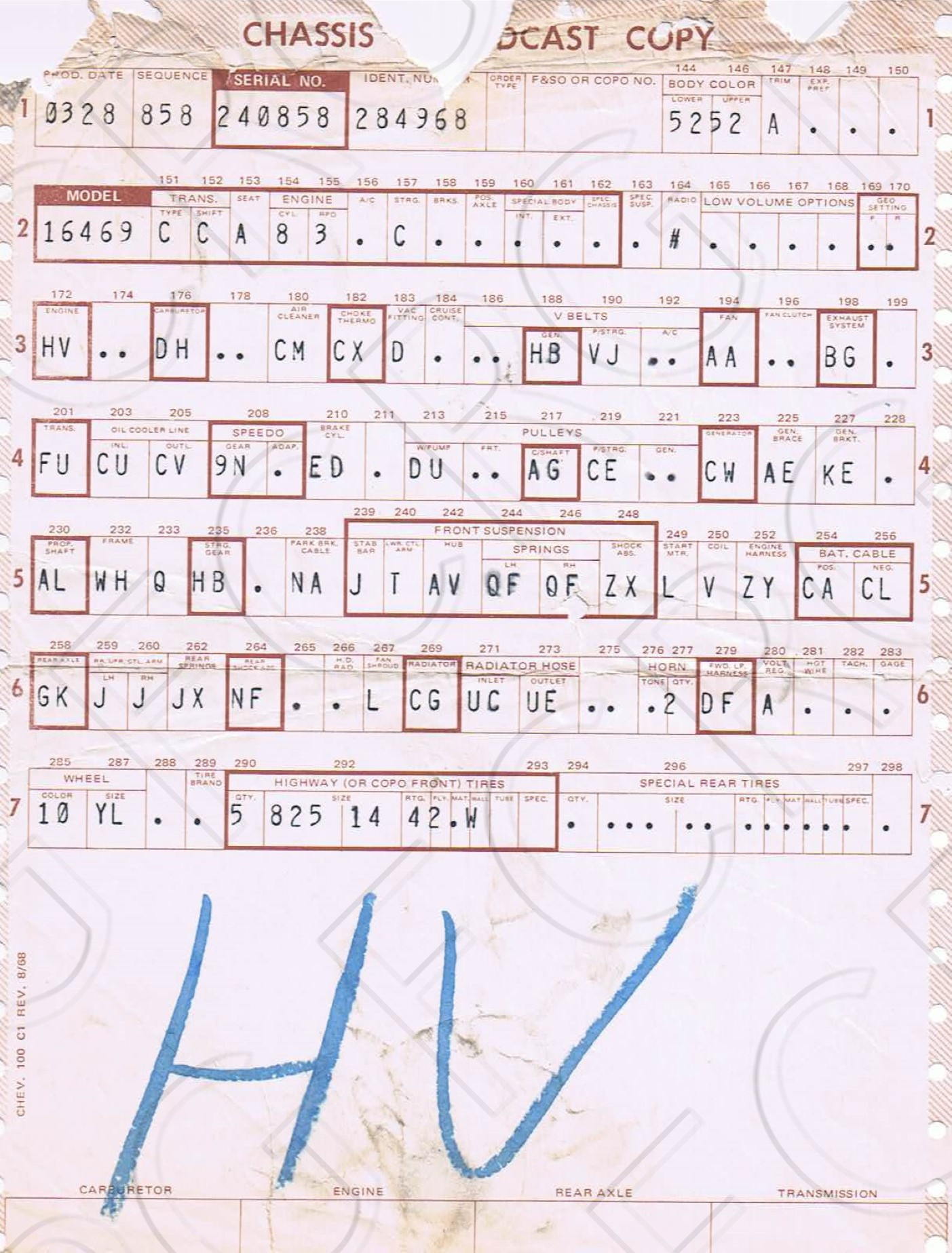

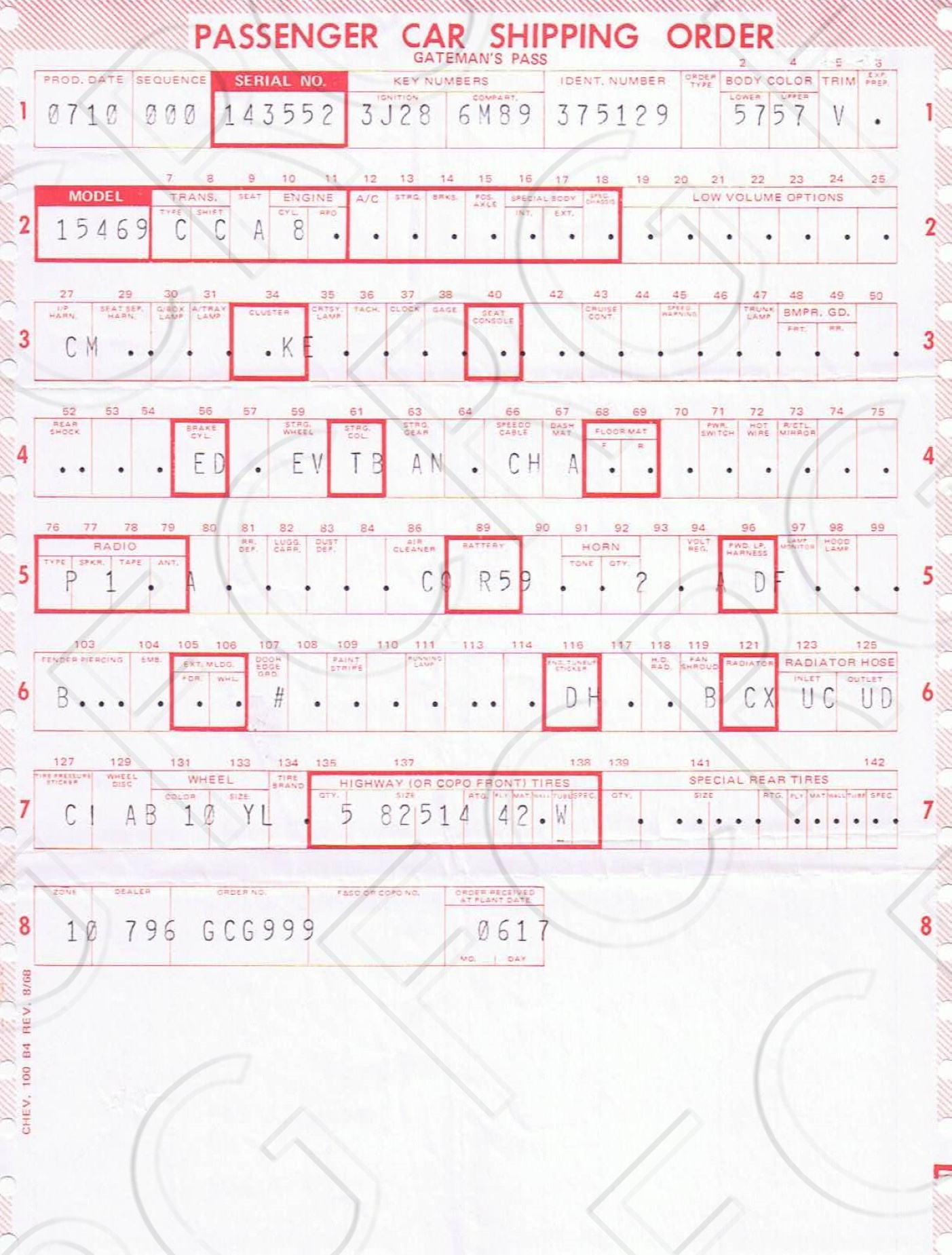

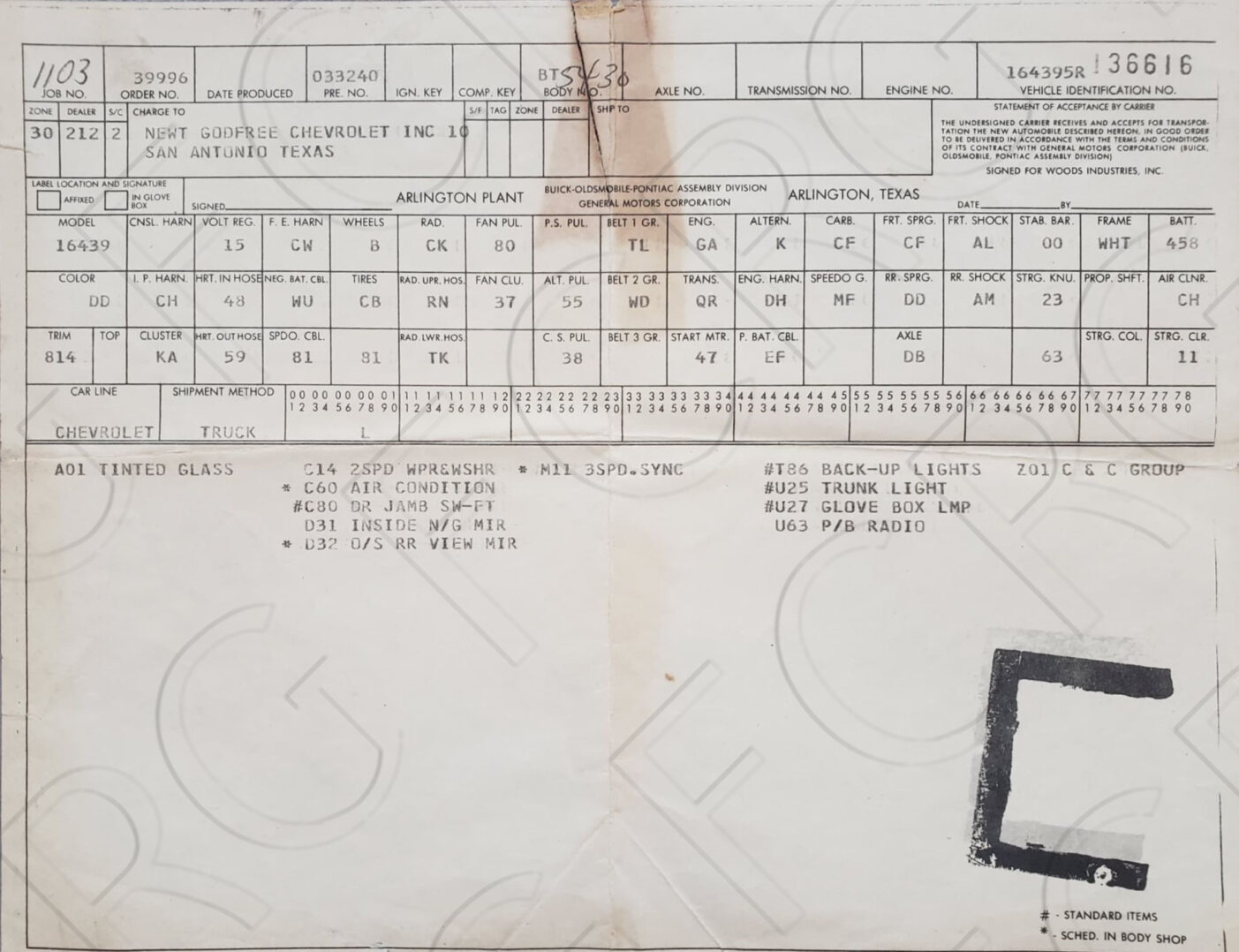

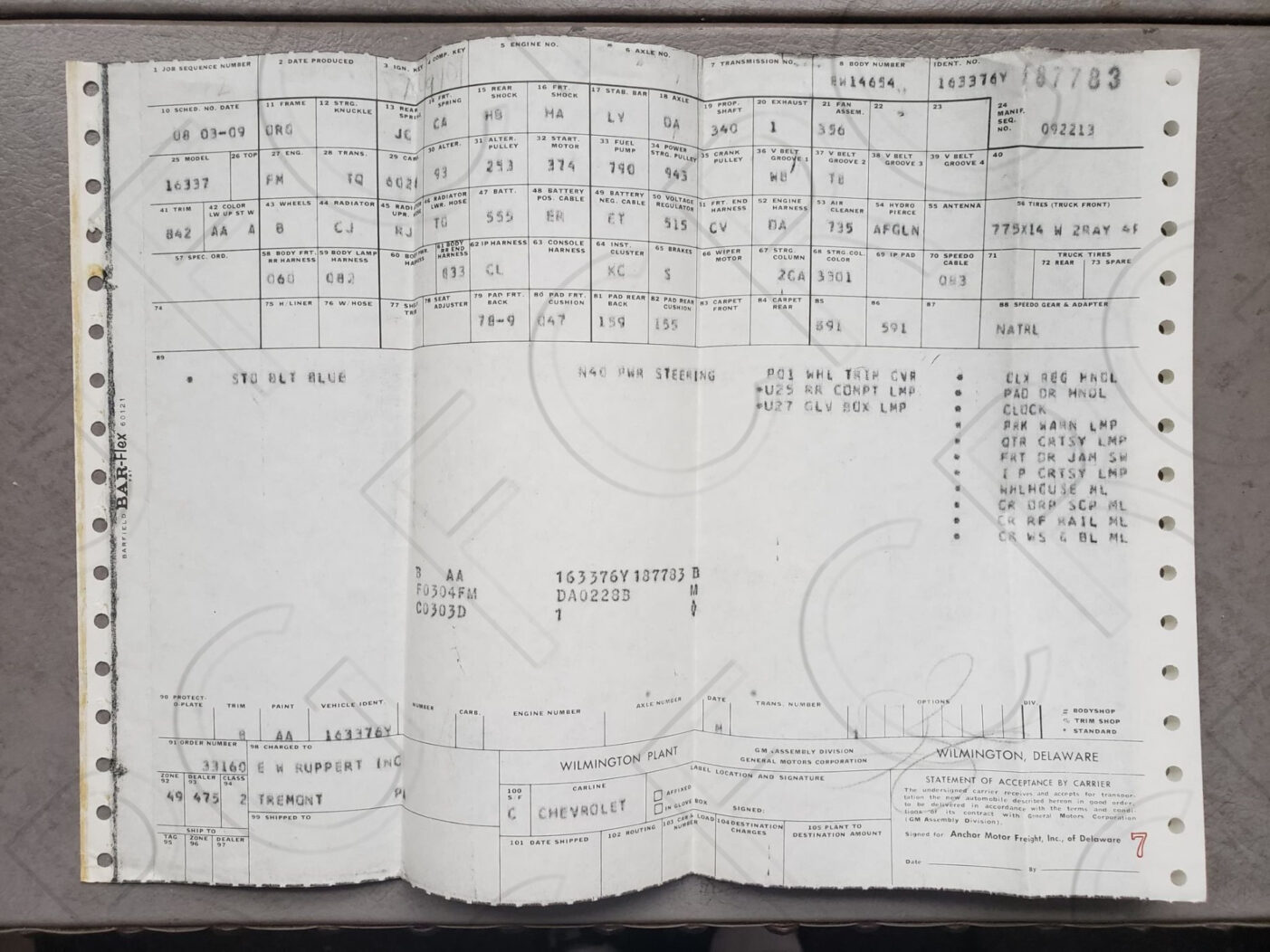

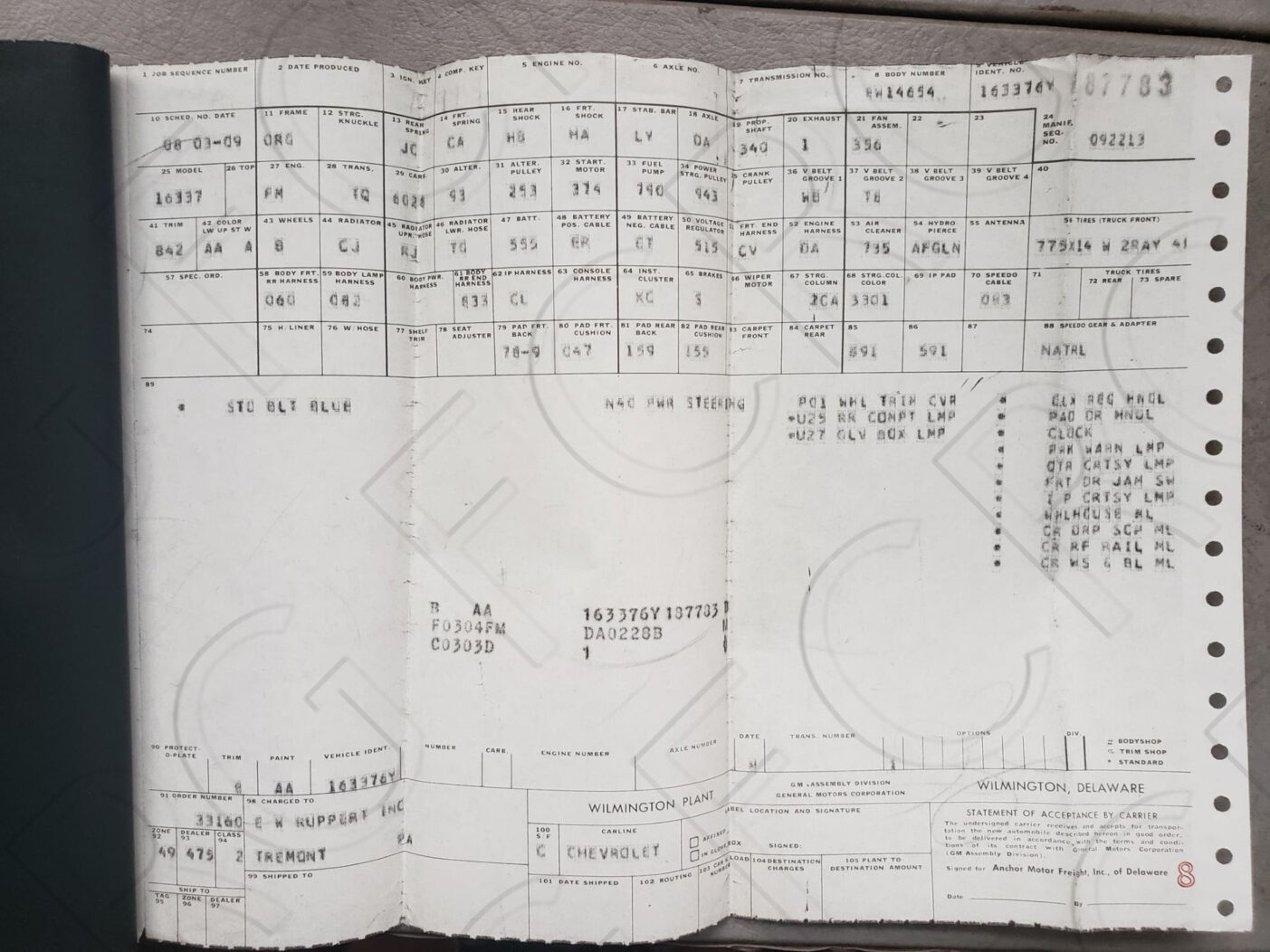

For 1966, they came out with separate body and chassis broadcast sheets, listing parts specific to the body and chassis of the car. This form with minor changes was used through 1970. There was also a “Passenger Car Shipping Order,” which was essentially a carbon copy of the Body Broadcast Copy. It contained the exact same info but was a different color.

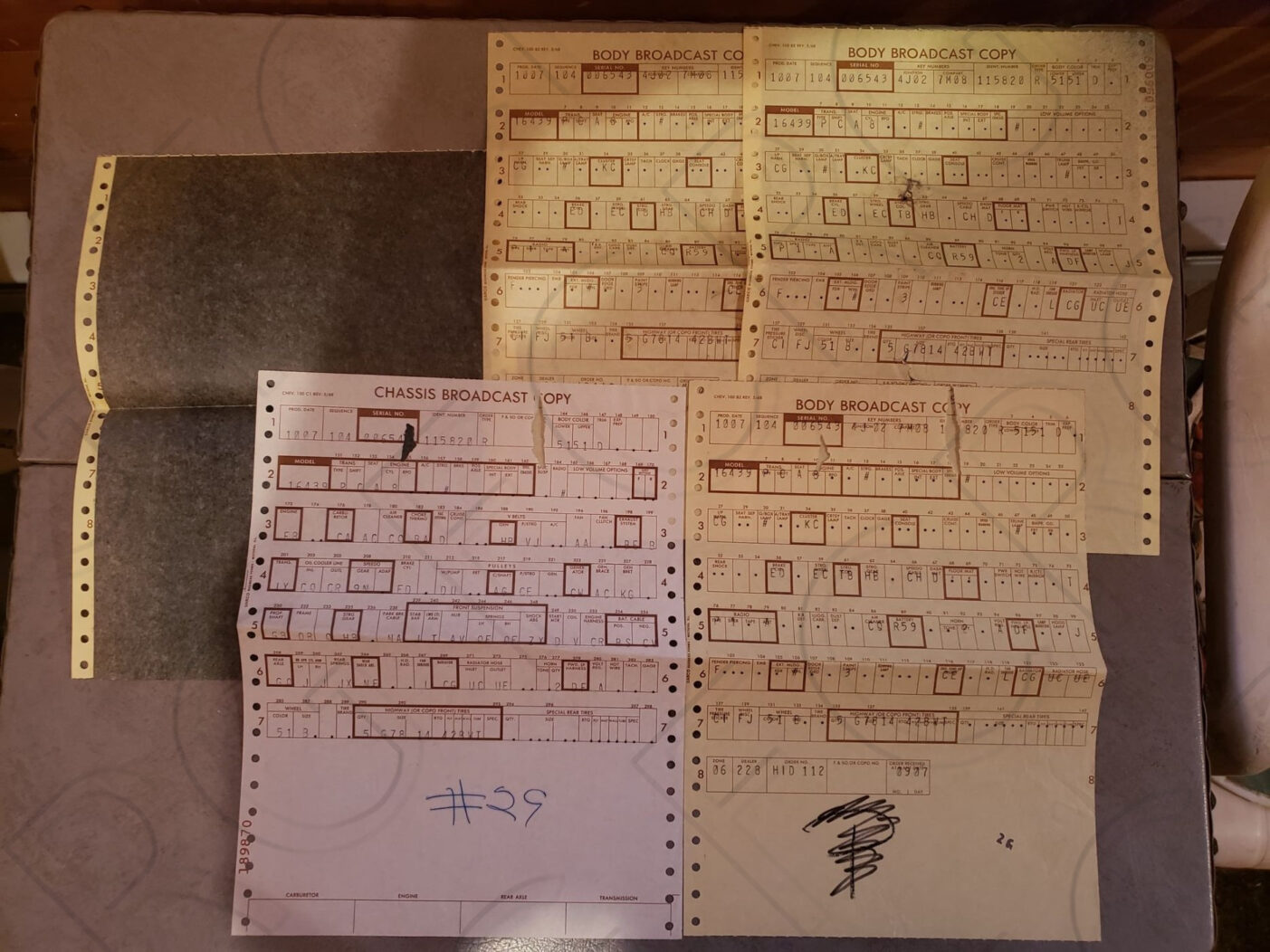

The following six photos show a pair of 69 broadcast sheets from Janesville, 70 body from Lordstown, 70 chassis from Janesville, 69 from St. Louis and a 67 from Lordstown. Note: The 66 and 67 Body Broadcast sheets from Lordstown showed the cowl tag information including accessory codes on the bottom two lines!

One of the questions I get asked the most is where do I look for the broadcast sheet in my car? That question really varies! The first thing to know is, yes, all Fisher Body plants used broadcast sheets! Most of the sheets in my collection came from groups of dealer paperwork. There was various paper tossed inside the car as it left the assembly plant. When it came time for the pre-delivery inspection at the dealership, some technicians threw out the papers while others placed it in the car’s file or with the owner’s manual in the glovebox. Some plants did leave them in “hidden” locations. Lordstown usually left them under the front and/or back seats. I’ve also seen them under the front carpet. Los Angeles left them on top of the gas tank in 69. I will cover Tarrytown, Flint and Framingham in another section of this article. Janesville, Atlanta and St Louis rarely left anything to be found. I’ve heard of one Janesville sheet being found under the front carpet. Two bonus photos show a 69 chassis copy from Los Angeles as found on top of the gas tank (credit Mattias Wikman) and the most broadcast sheets I’ve ever seen a dealer save from one car, a 69! Some still had the carbon paper attached and one had some Dusk Blue overspray!

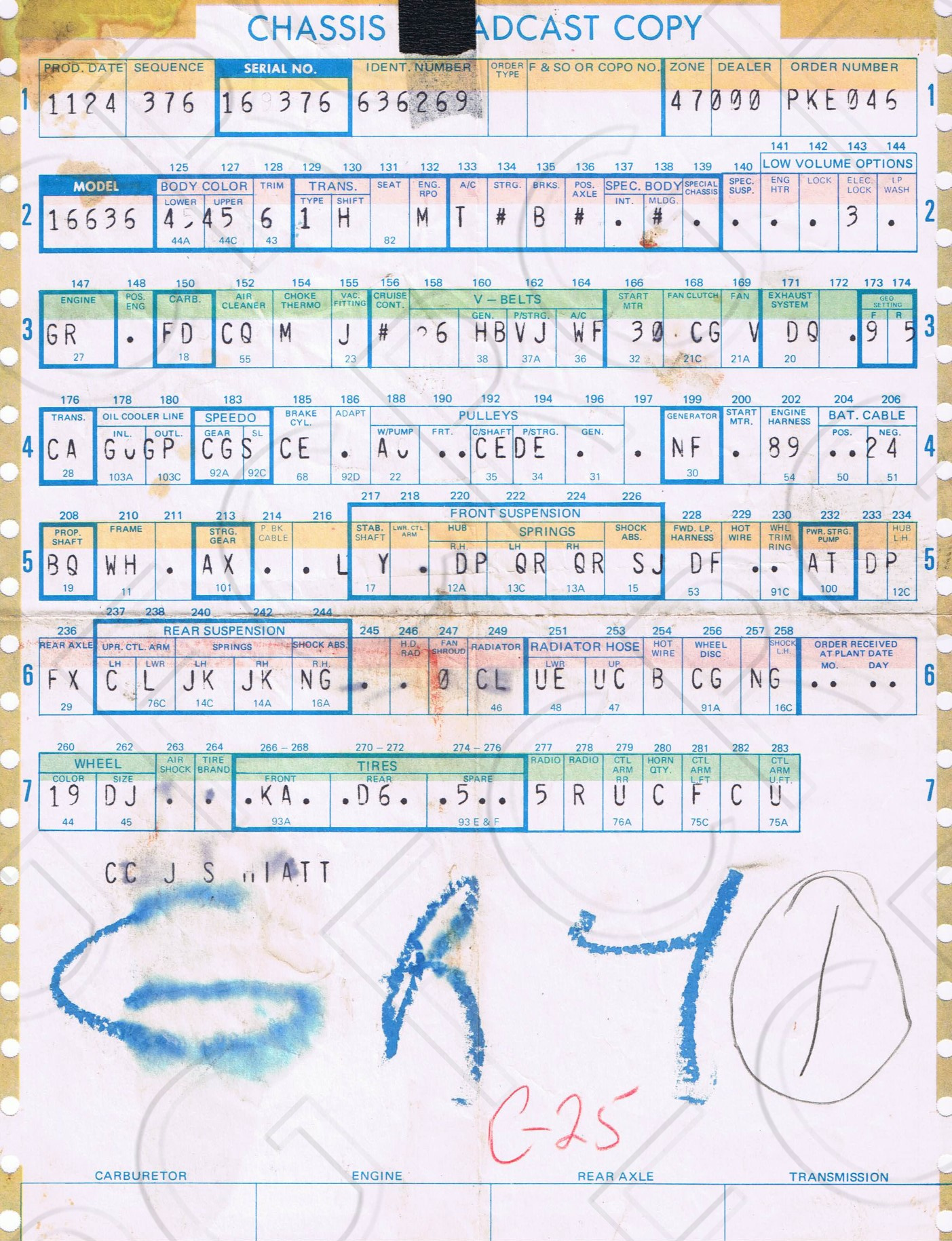

BOP Assembly Plants

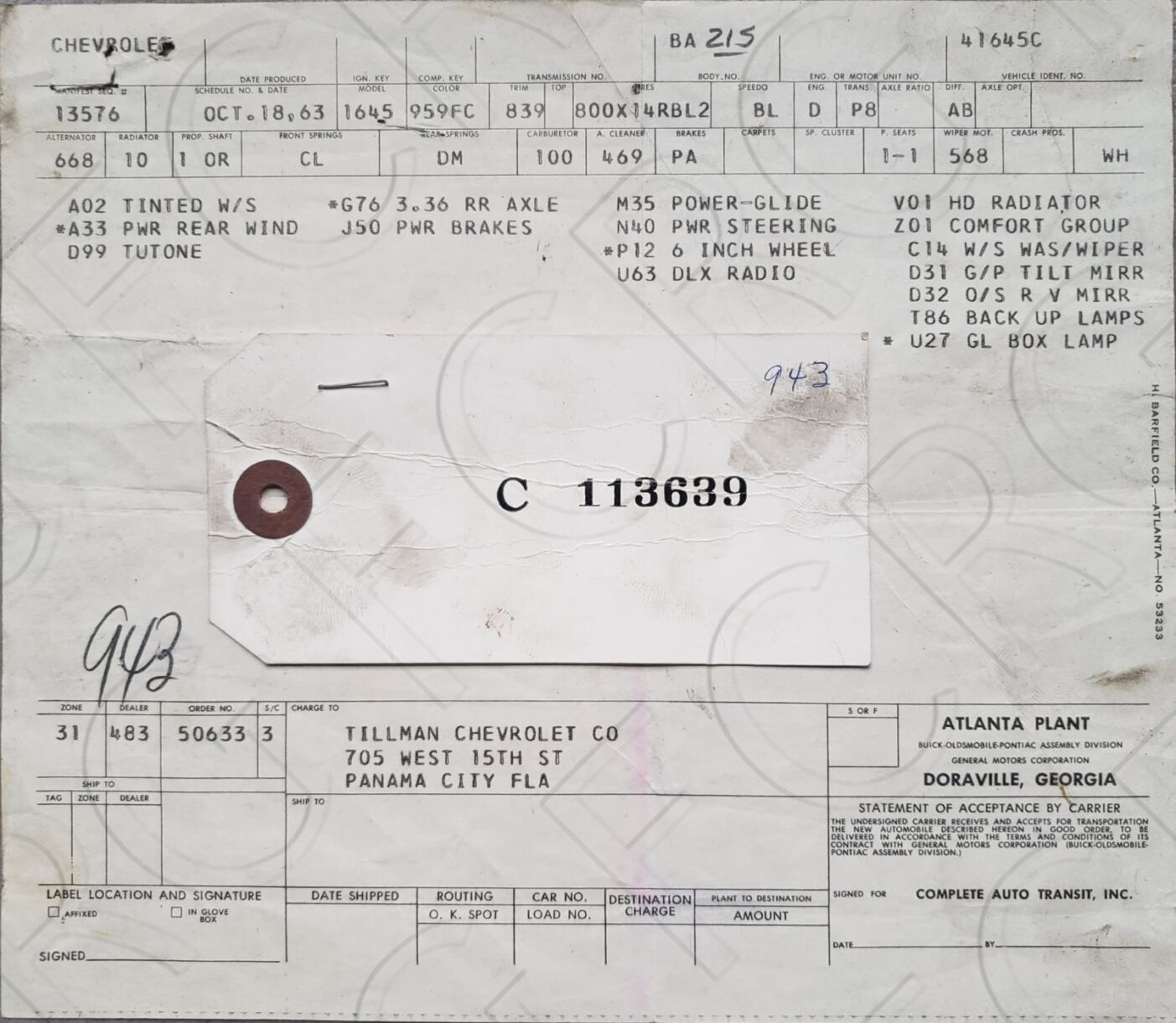

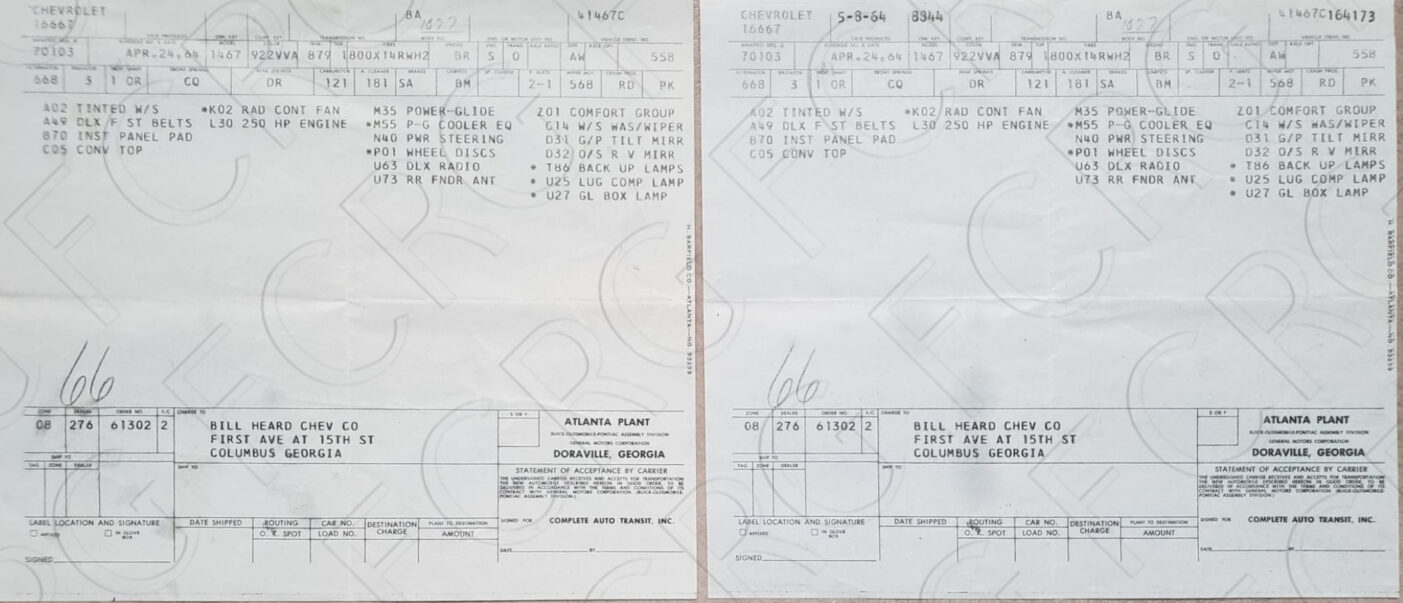

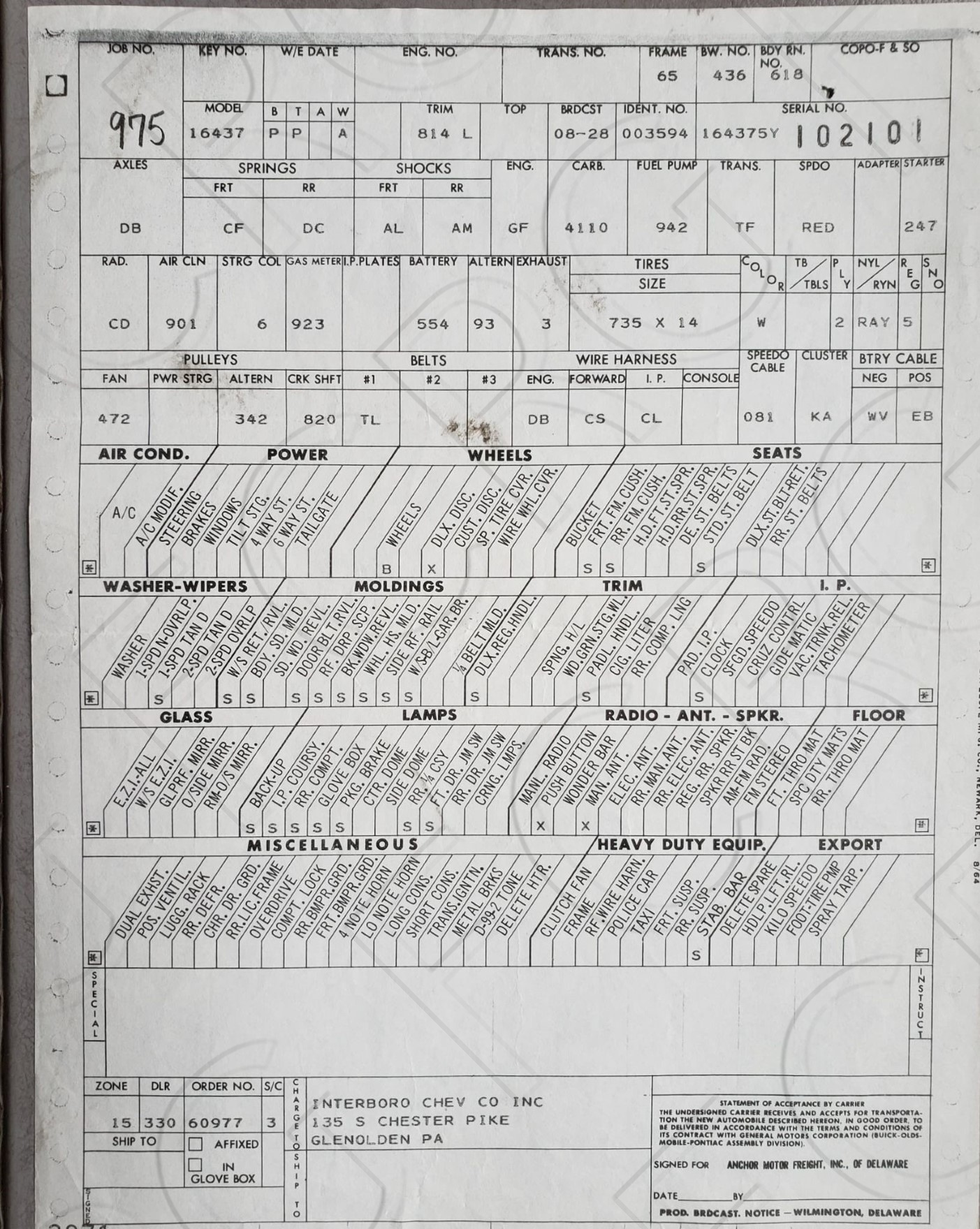

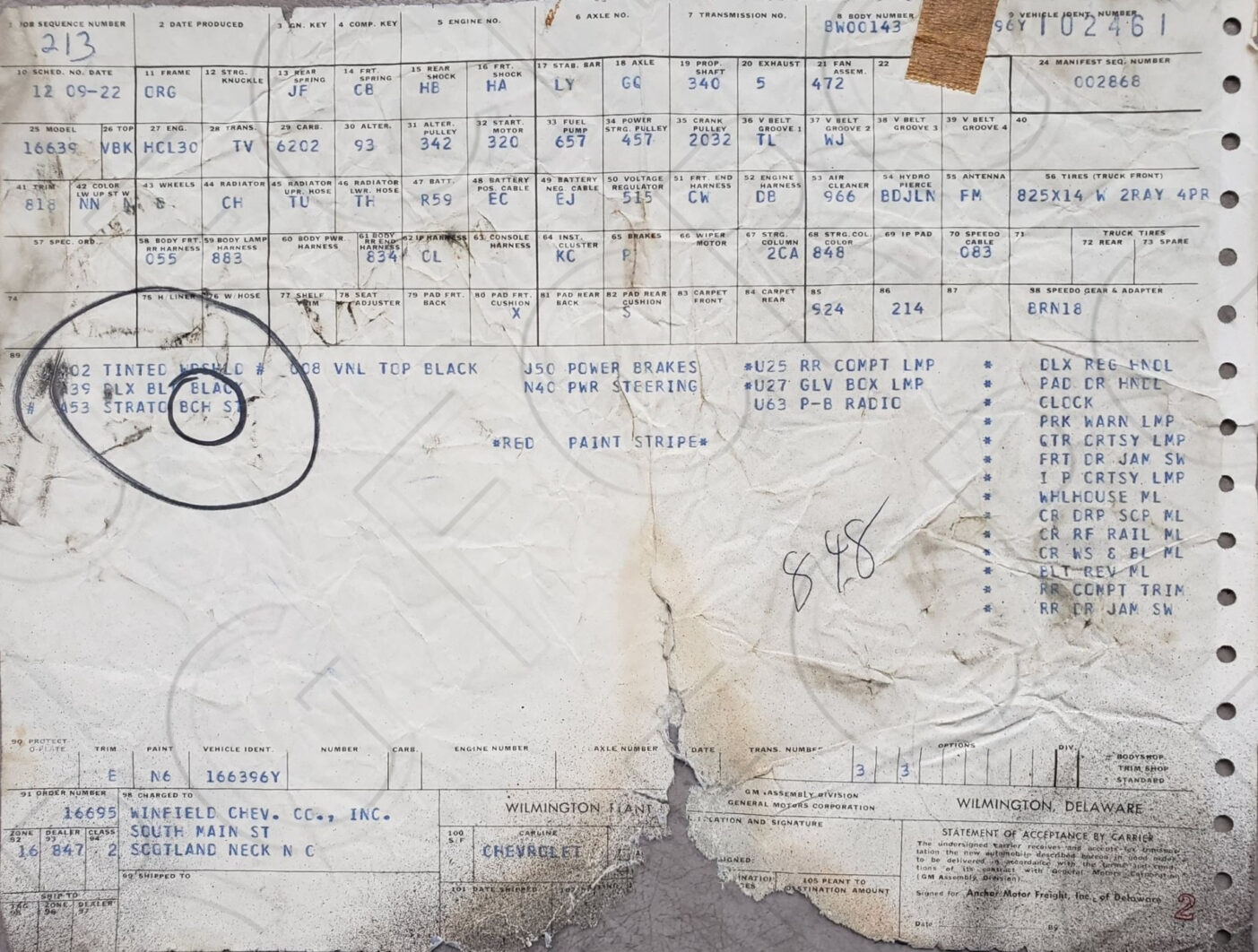

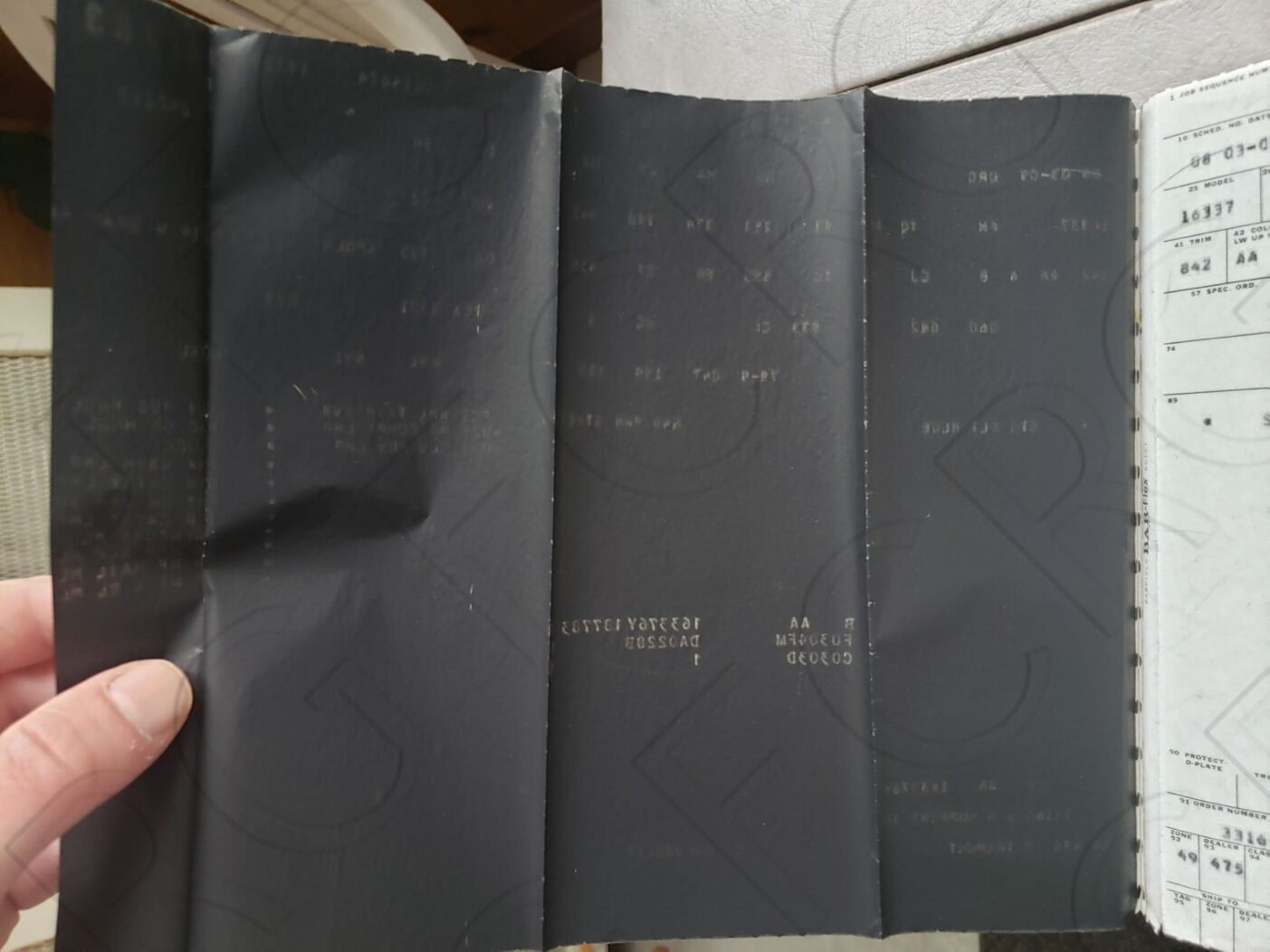

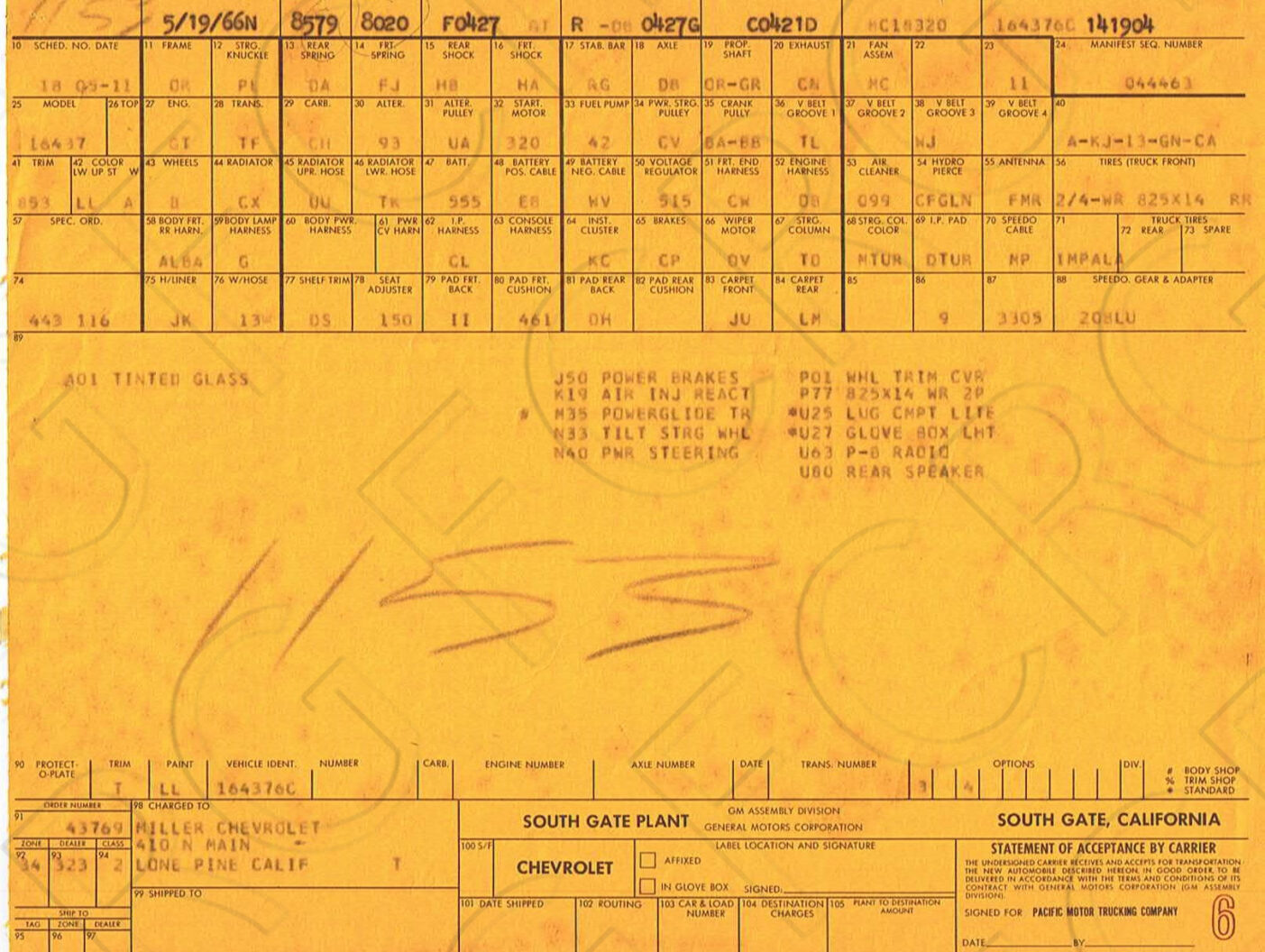

BOP assembly plants, which were a part of GM Assembly Division (GMAD), assembled Chevrolets, Buicks, Oldsmobiles and Pontiacs on the same assembly line! While they could also be called broadcast sheets, I’ve always called them build sheets. They are much easier to read. Most of the options are spelled out right on it! What’s cool is the same form was shared between the 4 car lines on the same assembly line! Chevrolet production at BOP plants started in 1964 and each of the plants had their own distinct form! By 1966, all plants used the same one. By 1970, the Janesville and Tarrytown plants joined GMAD and began using this form. That was also the first year Tarrytown started leaving something in the seats! The following photos show early build sheets from the various plants. These were originally multiple sheets with carbon paper between each and held together with a perforated edge. Typically what you find in the seats is a photocopied version of the original printed copy. Here is a guide of where to look:

- Wilmington

- All 4 sections of the seats: The bottoms and backs of the front and rear seats

- Above the hood insulation, if original

- I’ve seen one that was glued to the driver’s side of the cowl

- Doraville

- Under front and rear seat bottoms

- On two door sport coupes (not custom coupes), check behind the driver’s side rear armrest panel

- Southgate

- Above the hood insulation, if original

- 1968-1970 wagons on back side of panel in front of spare wheel cover.

- Any Southgate cars from 1967-1970 will have a handwritten piece of paper showing various interior information including carpet codes and some options.

- Arlington

- Check under the back seat. It’s not a sure thing but I’ve heard of several found in that location.

- Above the speedometer cluster in a 65

- On a 65 wagon, owner found one glued to the driver’s side rear wheel well.

- Tarrytown

- Starting in 1970, under rear seat bottom and inside bench seat back.

Photo Gallery:

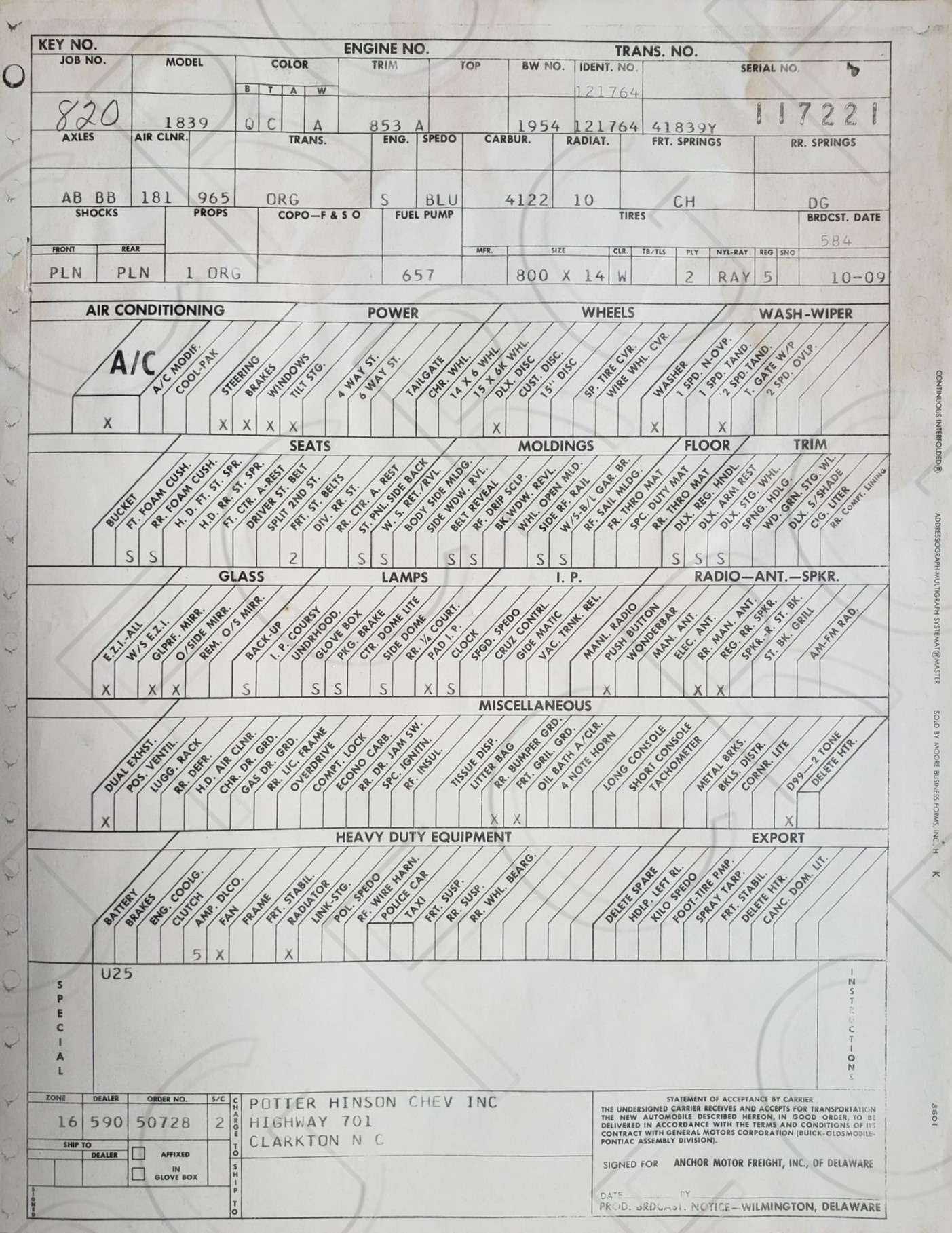

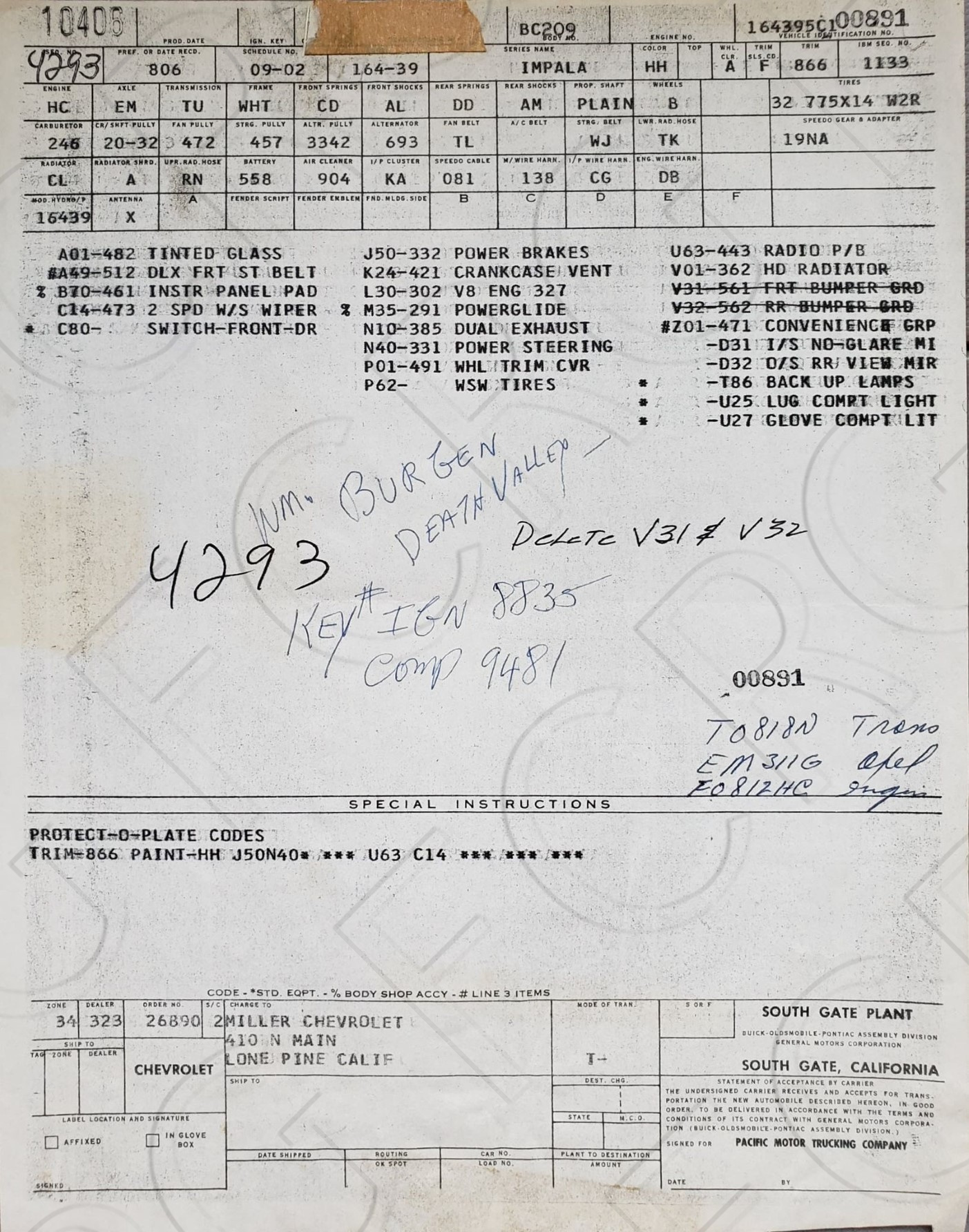

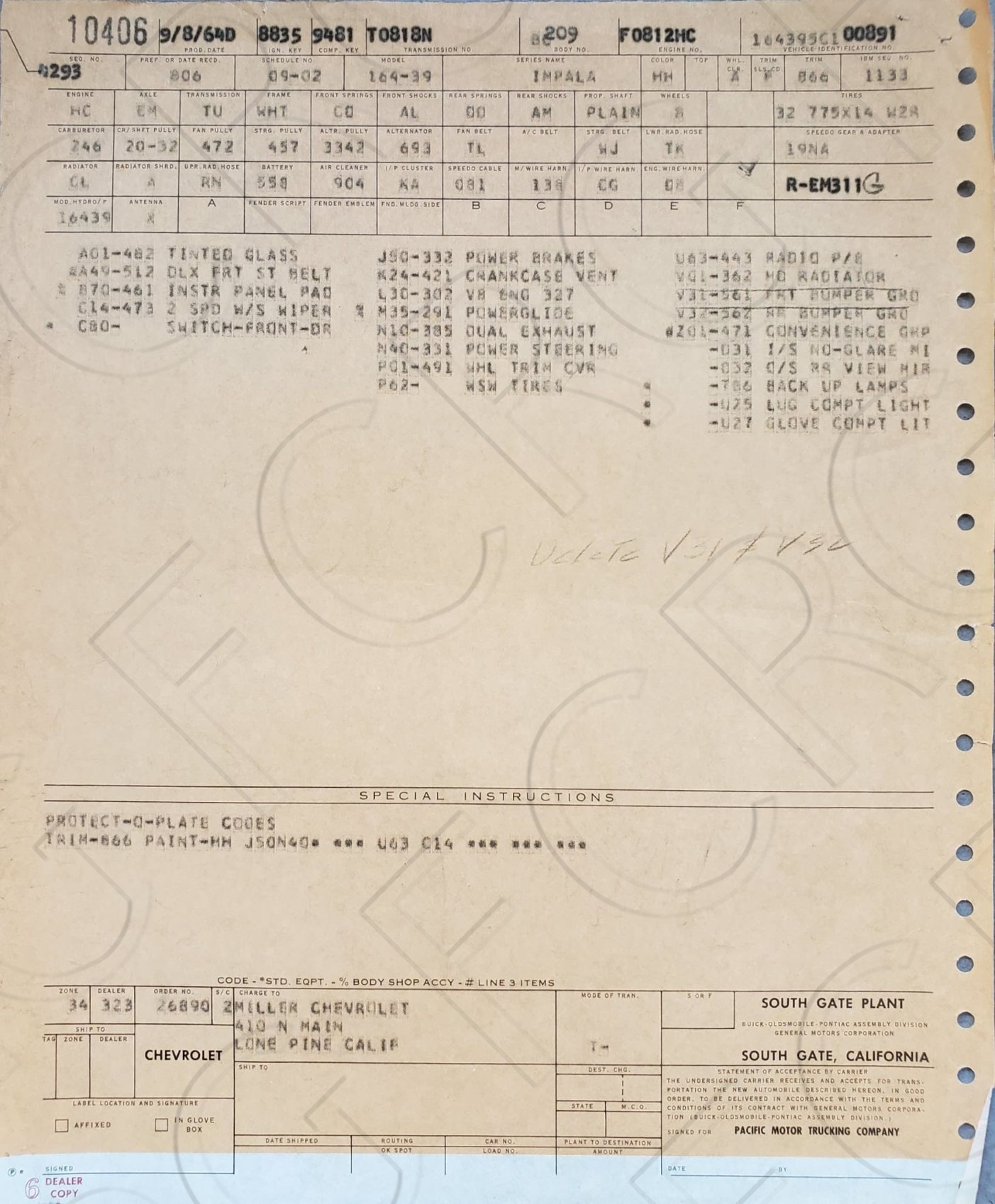

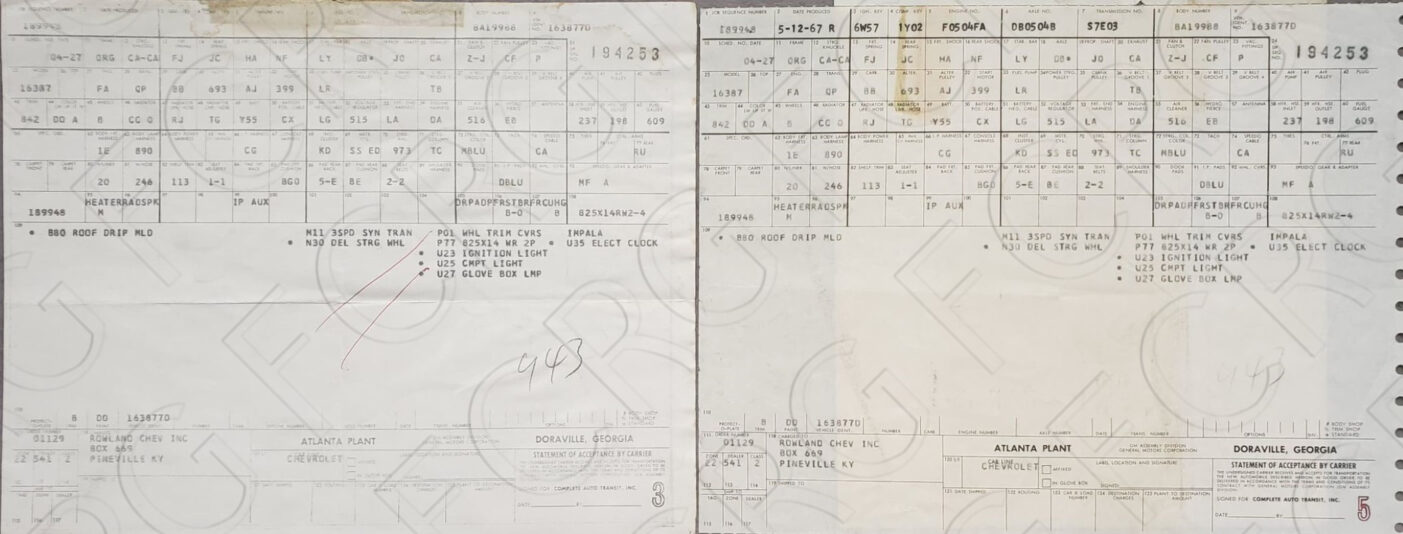

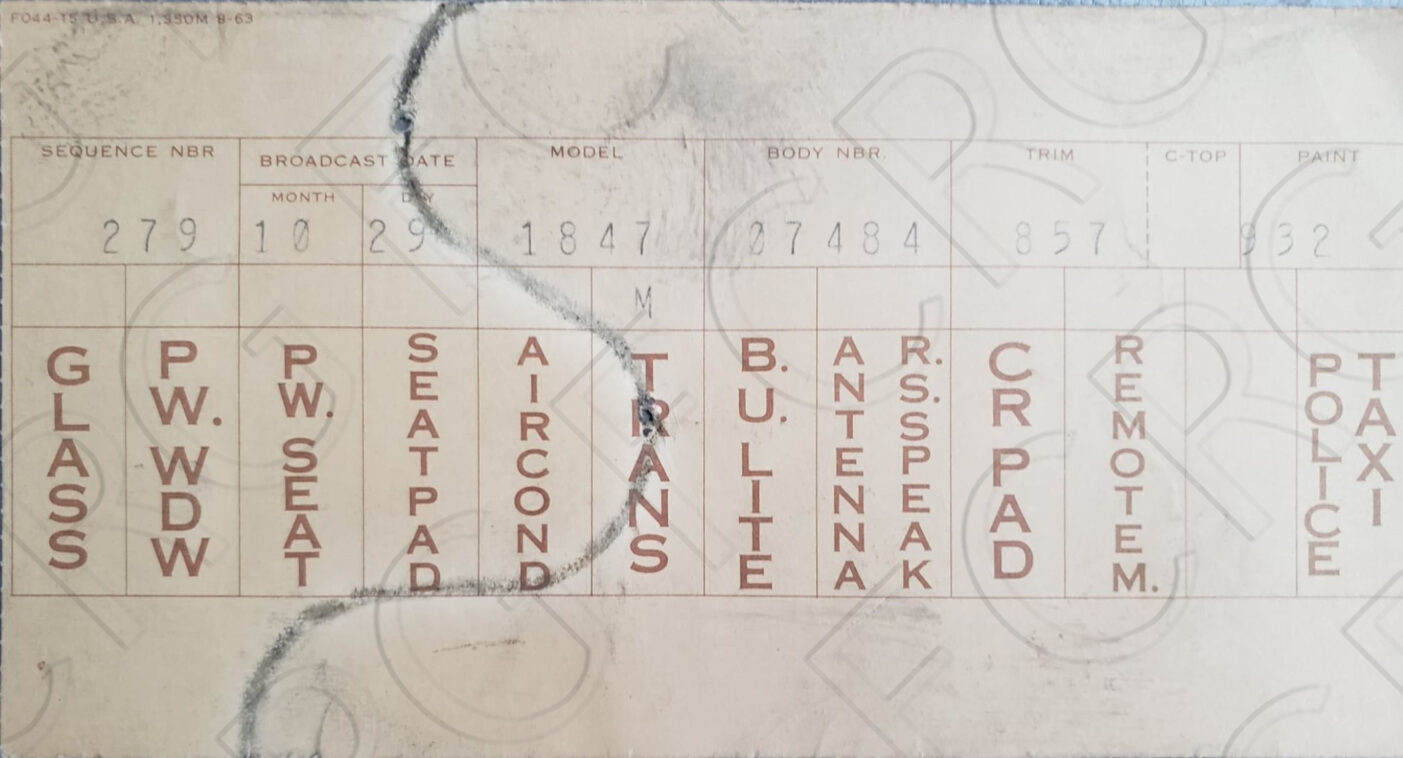

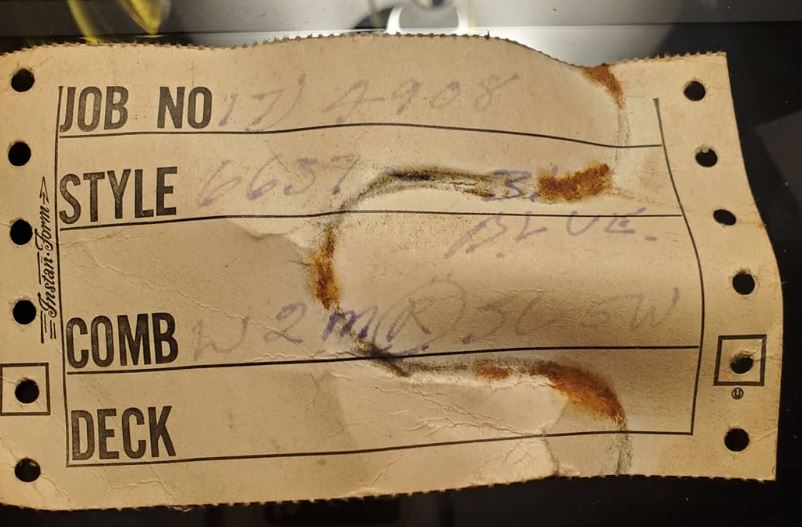

First group of photos are build sheets from 1964’s. The first 3 are Doraville and the last one is from Wilmington. Note in the first picture the last six of the serial number is not printed. It is printed on that tag in the photo, which I found with the sheet inside an owners manual! They both have the same job number, 943. The copies Doraville left in the cars did not yet have that filled in. In the 2nd photo, both sheets are from the same car but the copy on the right has the serial number and other info typed in. The third photo shows the backside of those sheets. Notice the carbon strip so the typed info would transfer to the copy underneath it! The last photo shows an early sheet from Wilmington. The form changed mid model year. but looks almost identical to this one.

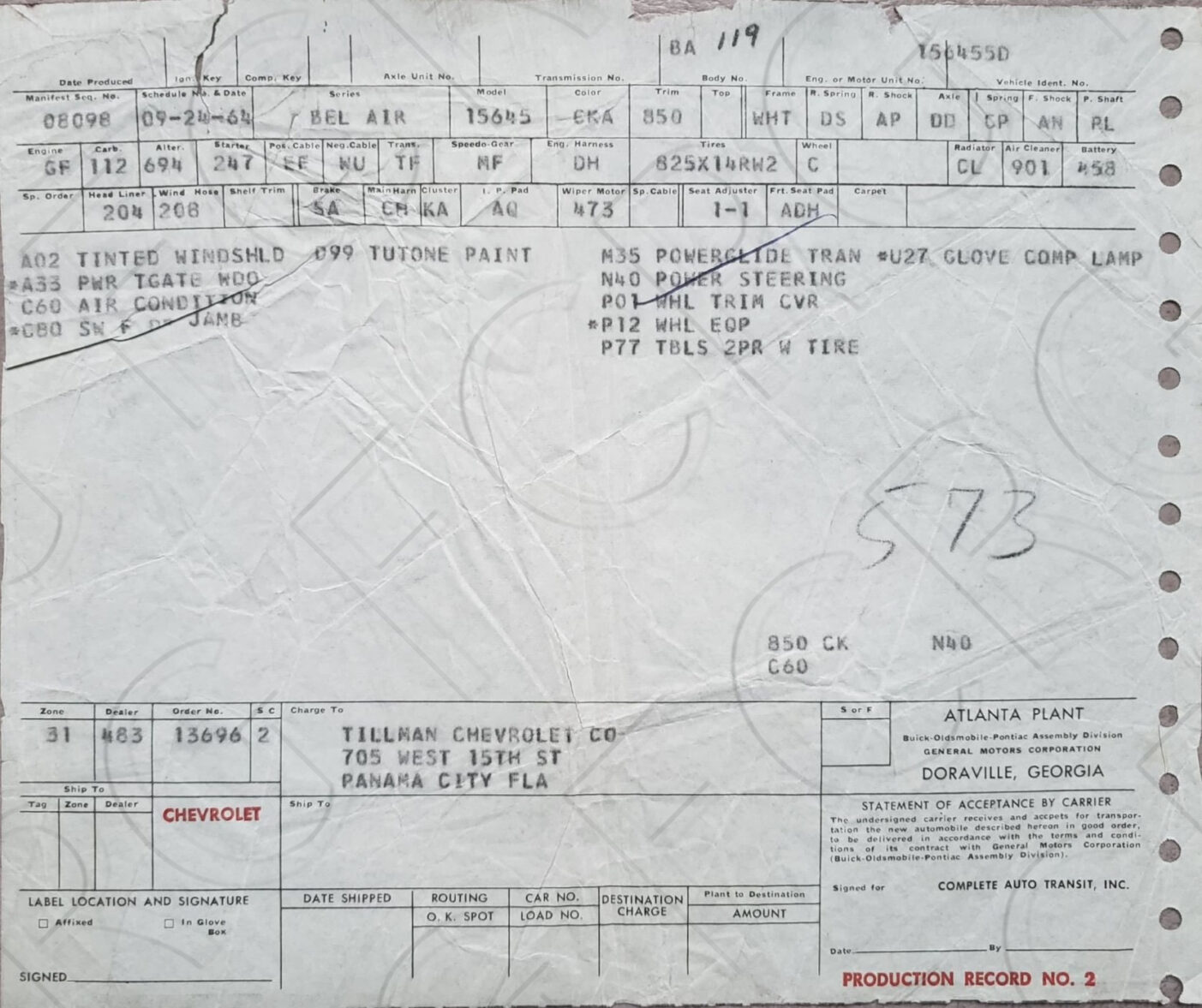

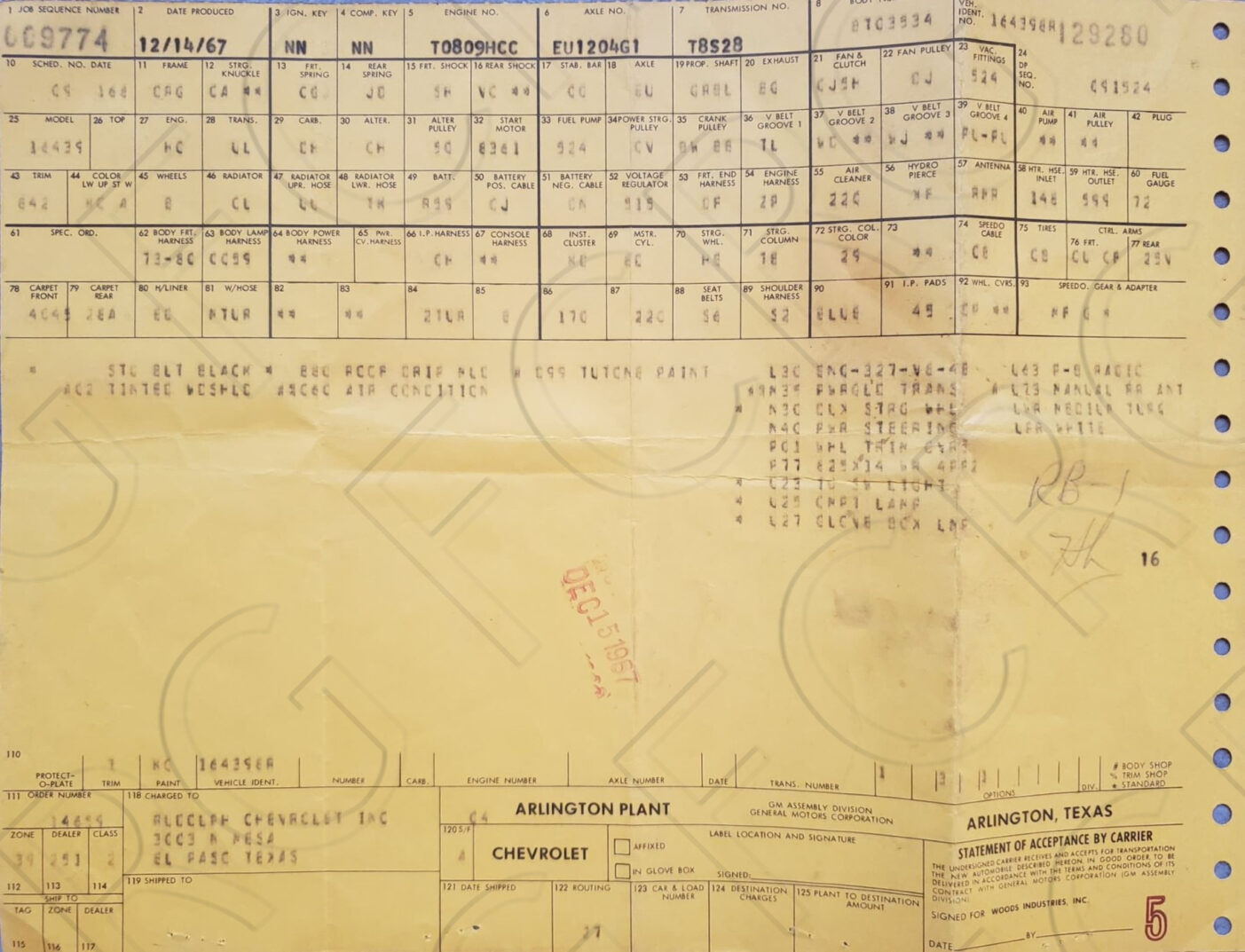

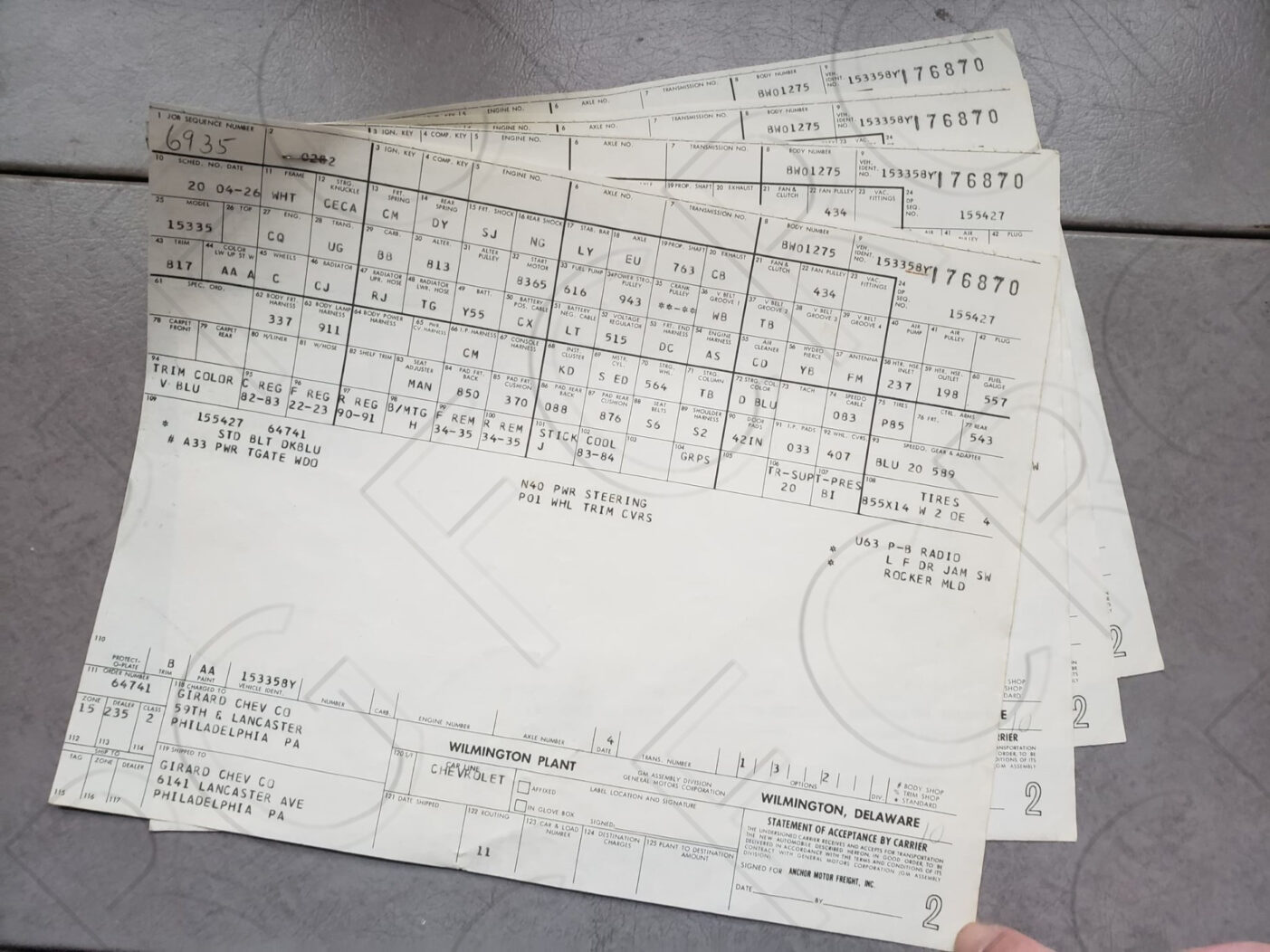

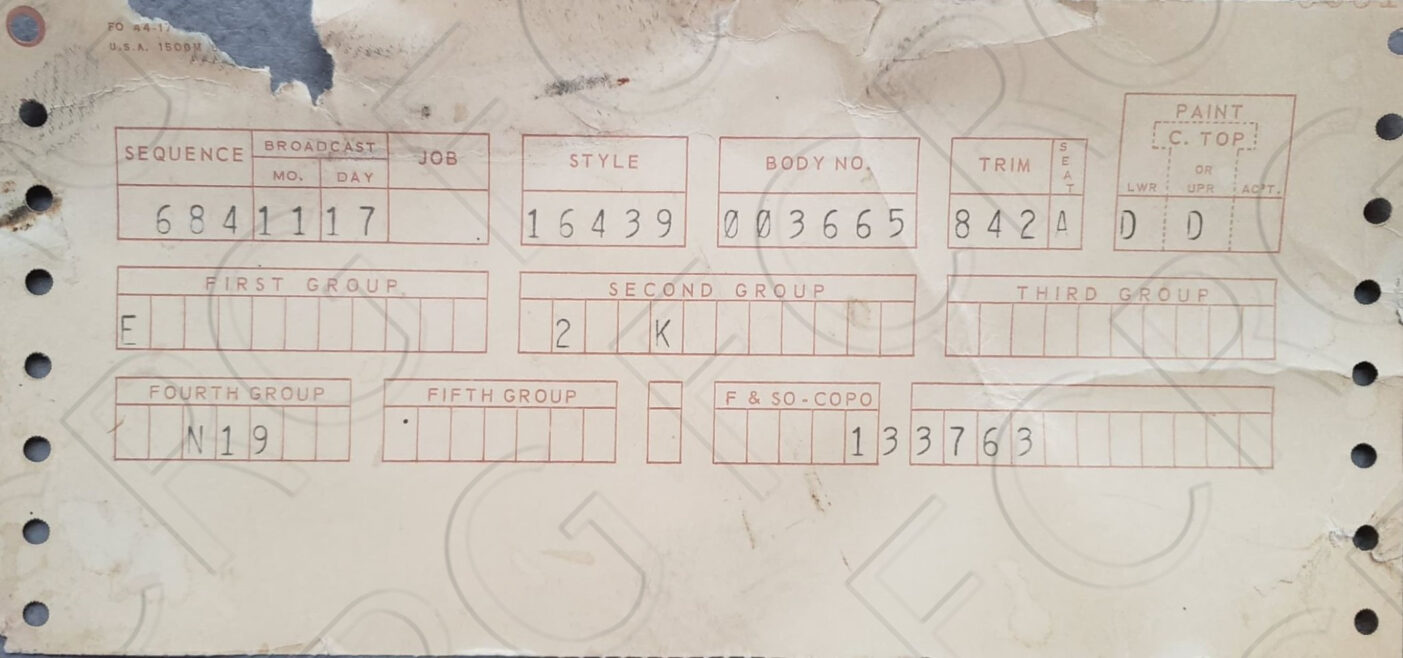

The following photos are from 65’s. The first two are from the same Southgate built Belair. The 2nd is a later copy that has the drivetrain codes typed on the top line. Third photo shows an original from Doraville with the feeder strip edge. Next is from Arlington and the final two are from Wilmington. The last photo shows 4 sheets from the same car. I’ve seen this multiple times from cars built there. They were left on the seat of the car and stuck in with the owner’s manual. I believe they were stapled together at the plant.

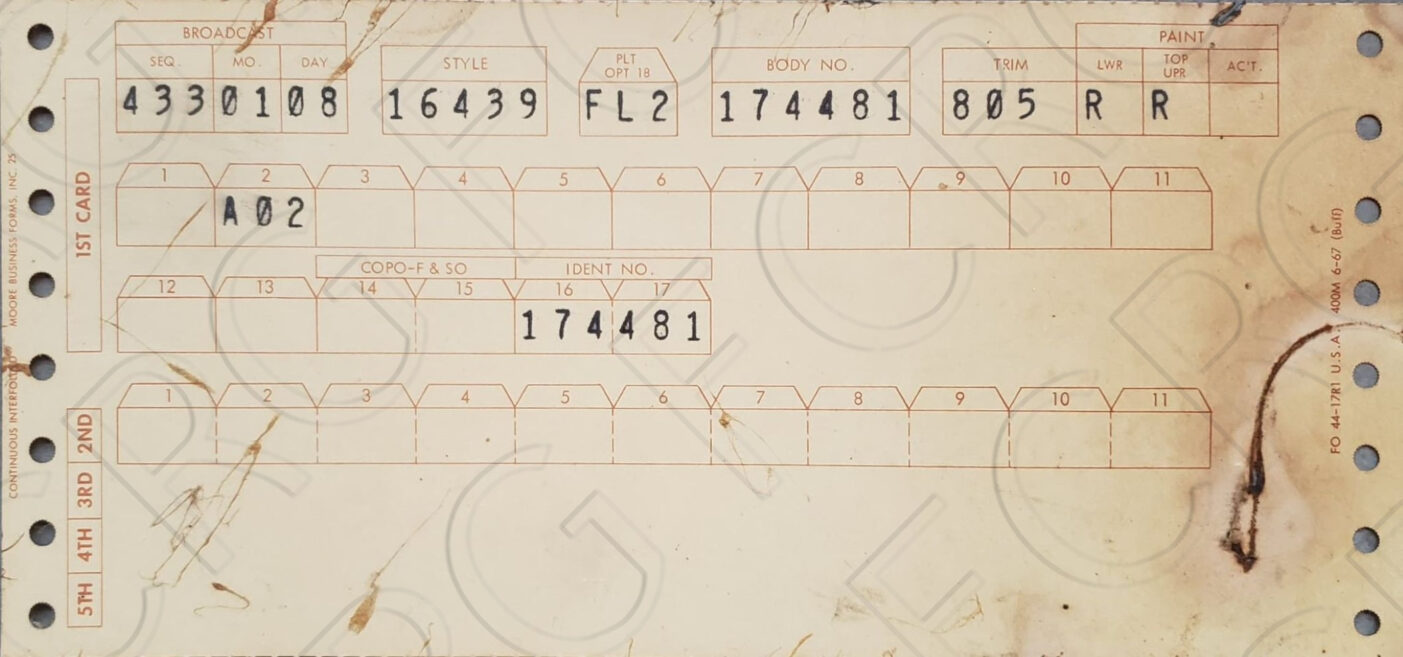

The common form used between BOP plants starting in 66 had multiple sheets with carbon paper in between. You can see the numbers in the bottom right. Some Southgate and Arlington copies you find have a CH printed in that location, probably to help show it was being used on a Chevrolet. The packet of sheets started with #1 as the top copy and I’ve seen as low as #8 on a Wilmington car. The first row shows a #2 copy, the only one I’ve seen and it has a carbon backside! This row also shows the only Wilmington sheets I have seen with carbon paper still attached! By the time it got down to the #7 and 8 copies, they knew the drivetrain codes, which were filled in on the top line or the Protect-o-Plate was imprinted on the document.

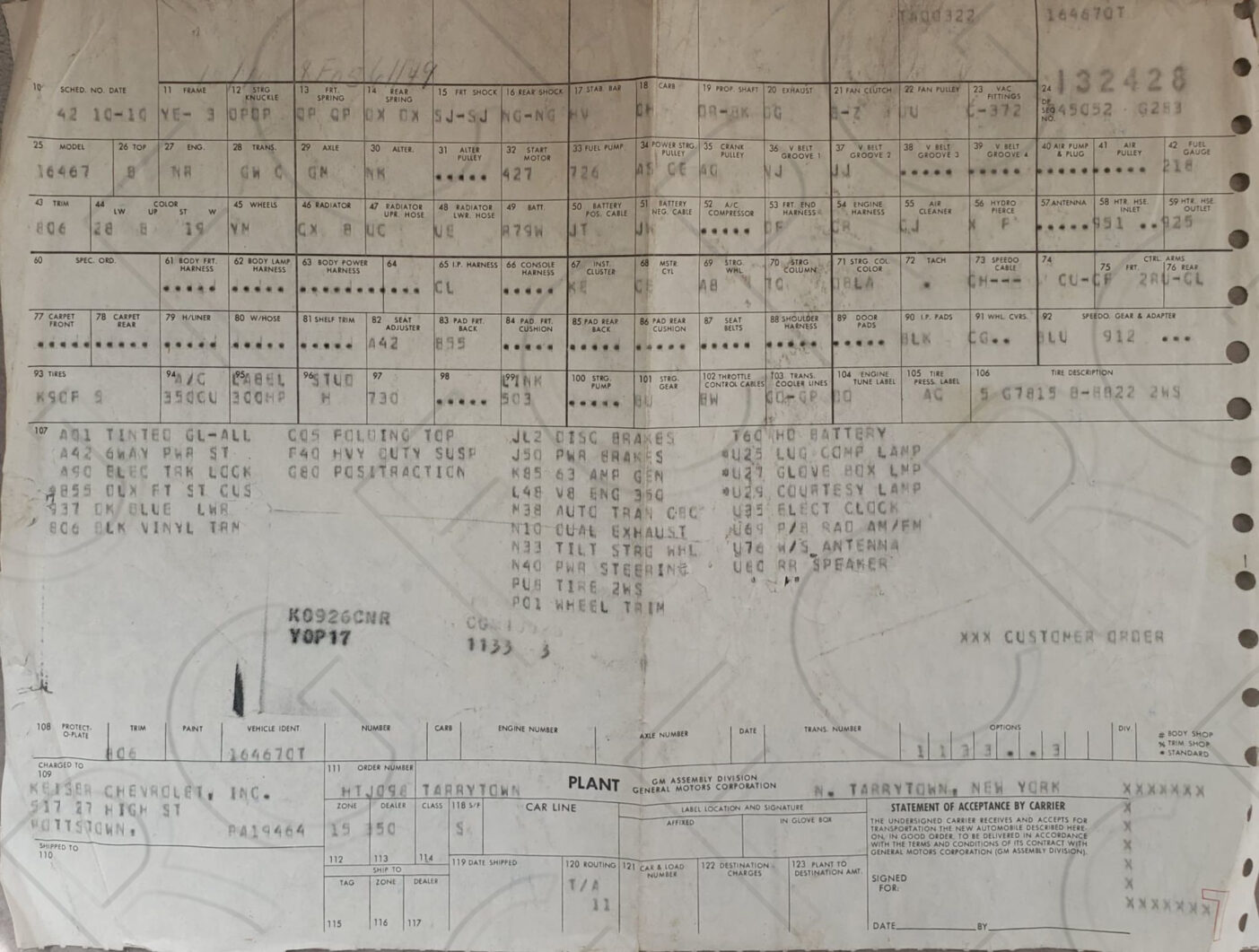

The 2nd line shows sheets from 66 Southgate, 67 Doraville, 68 Arlington, 68 Wilmington (4 stapled together like the 65 shown above) and 70 Tarrytown.

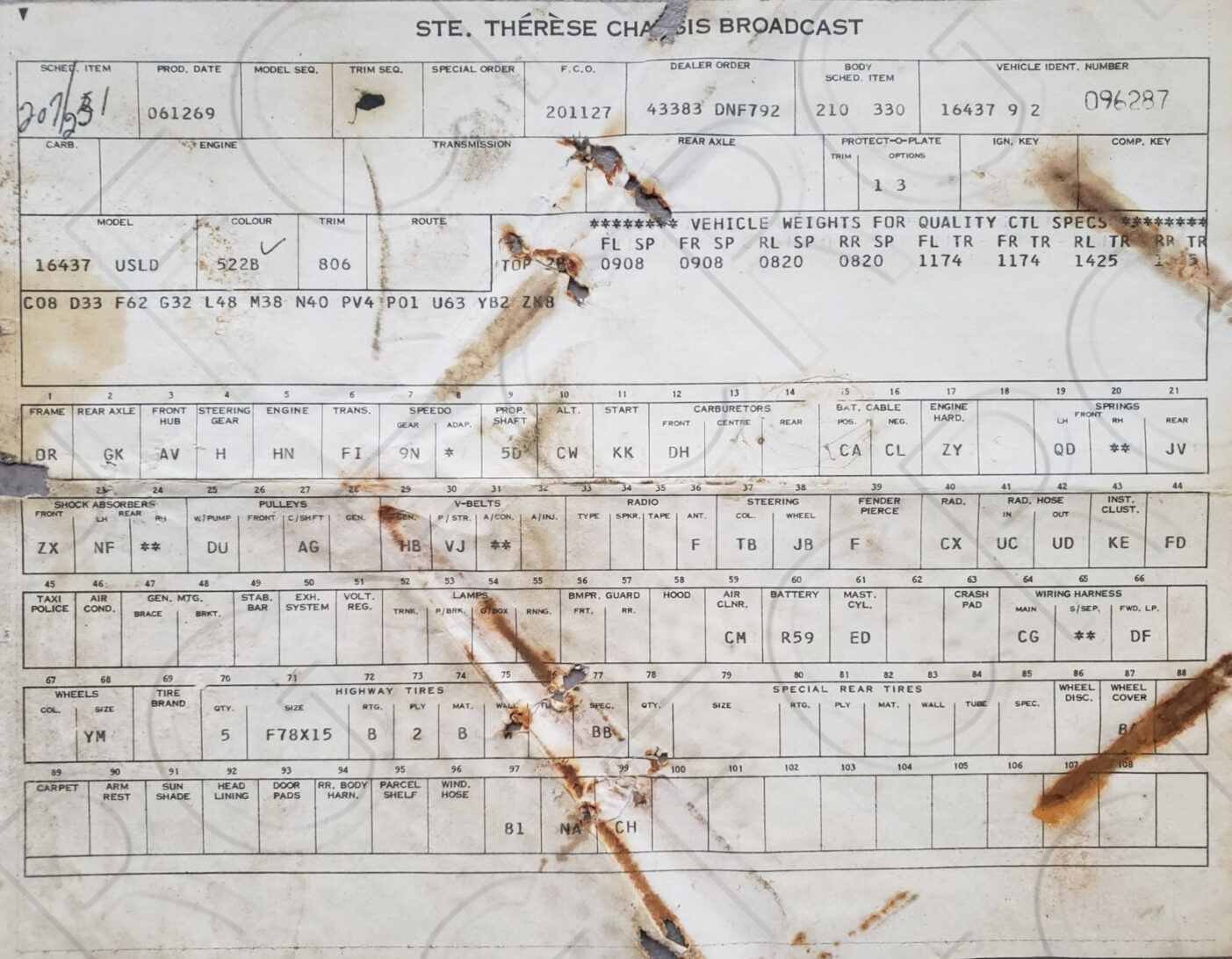

Canadian Plants

Oshawa and St Therese both left papers in the seats. Oshawa used a strip of paper that had the RPO codes on it. St Therese used a broadcast sheet. The only ones I have seen have the heading “St Therese Chassis Broadcast.” I have not seen one for the body side. Both plants left them in the front and rear seat bottoms. I’ve found the top part of a St Therese sheet above the hood insulation in a 67 Caprice and other copies have been found above the gas tank. The 67’s are hard to find in good condition as the paper was very thin. Shown below are 67 and 69 sheets from St. Therese.

Seat Tags

Some plants left smaller pieces of paper behind with minimal information that was specific to the interior. I’ll detail that in the following list:

- Flint and Framingham used a small 5″ x 8″ card that had the cowl tag information on it. Look in all four sections of the seats. I’ve also recently discovered Framingham glued them to the rear armrest panel on coupes.

- Southgate and Arlington copied interior information from the build sheet onto a piece of paper, which was left in the seats.

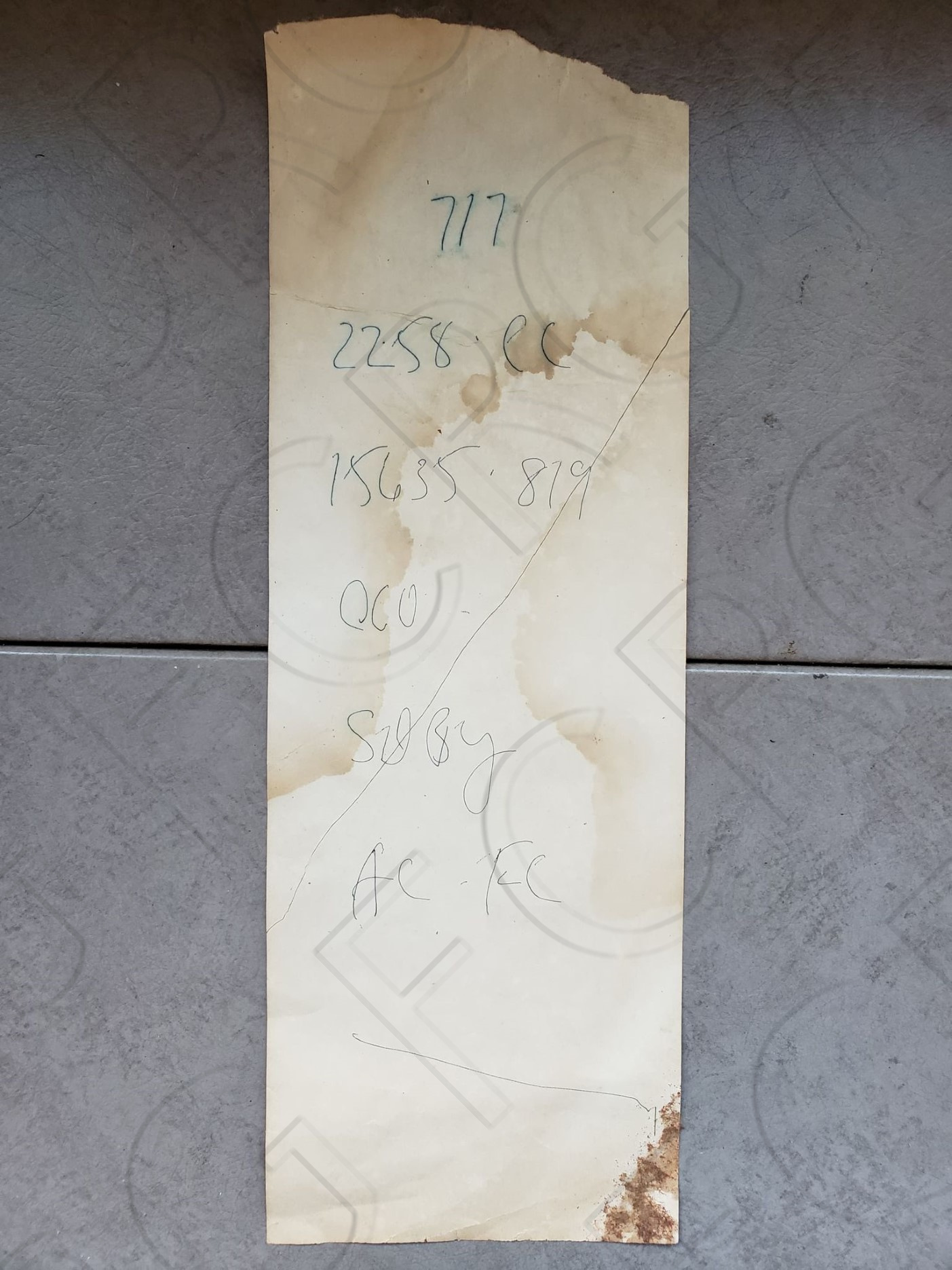

- Los Angeles used a small card that had cowl tag info handwritten on it. I’ve only seen a few of them and they are usually found inside the front seat or rear seat backs. In the example shown, top line has the job number and sequential body number. 2nd line has body style and interior code. 3rd line has accessory codes from the cowl tag. Thanks to Jason Wolfe for the pic.

Bonus Photos: Hiding Places!

- Build sheet in front seat back of 1964 wagon from Wilmington

- Build sheet above hood insulation in 1967 Caprice from Wilmington

- Build sheet in rear seat bottom of 1969 Impala from Wilmington

- Broadcast sheet from Lordstown 1969 Impala convertible in the springs of the bench seat bottom

- Seat tag from 1968 Caprice from Flint as found inside the bench seat back

- Build sheet from a Doraville 65 coupe glued to backside of driver’s side rear armrest panel.

Decoding these documents

I have been working on decoding build sheets for years. To date, I’ve documented the codes from over 1,100 build sheets and 800 broadcast sheets! I’ve only decoded a small fraction of the boxes. Any examples you can share would be appreciated.